Tipos de máquinas de enchimento e selagem

Devido à grande variedade de formatos de sacos usados para embalar itens, os modelos e estruturas de máquinas de enchimento e selagem também variam muito, o que se reflete principalmente nos dispositivos de ensacamento e selagem. Geralmente, há dois tipos: um é uma máquina de enchimento e selagem para fazer sacos, e o outro é uma máquina de enchimento e selagem para alimentação de sacos.

Tipo de máquina de formação, enchimento e selagem de sacos

É adequado para a produção de sacos de travesseiro, sacos selados de três lados e quatro lados, sacos planos e sacos autoportantes. De acordo com os diferentes formatos de saco, pode ser dividido em:

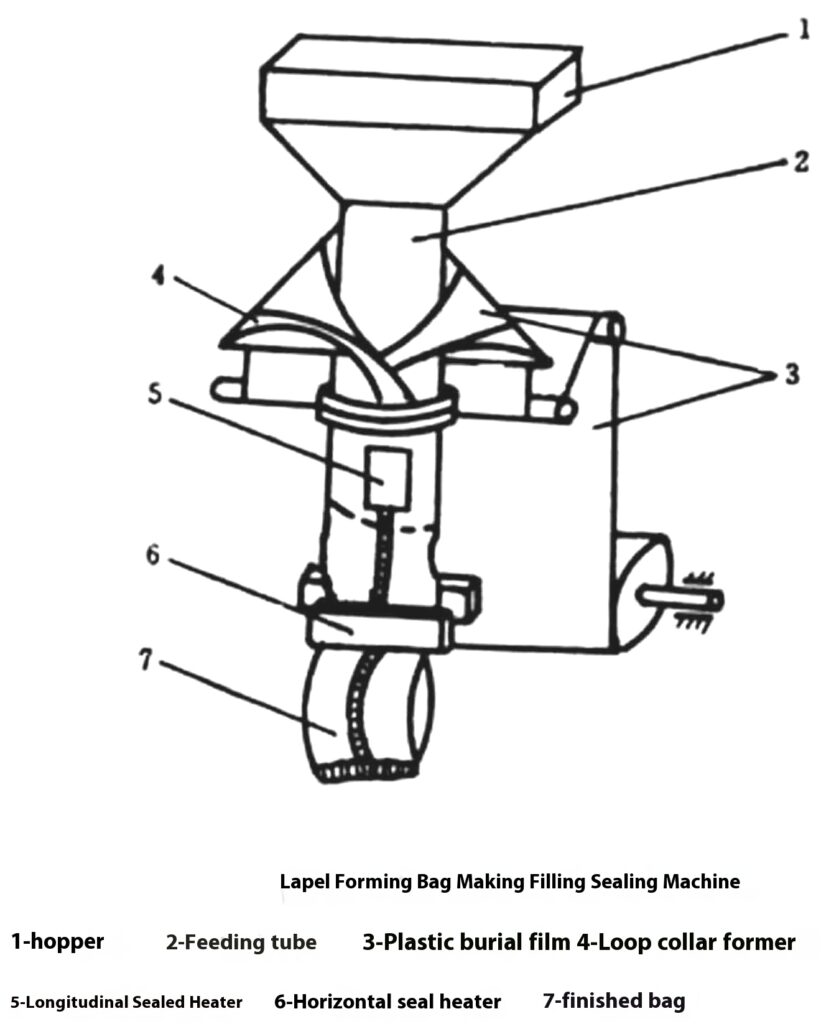

Máquina de enchimento e selagem para fabricação de sacos de lapela

Utilizada para a produção de sacos tipo almofada, a figura é um diagrama esquemático de trabalho de uma máquina vertical, intermitente, de enchimento e selagem de sacos com lapela, que pode concluir a fabricação de sacos de filme plástico, selagem longitudinal (junta de sobreposição ou topo), enchimento, selagem e corte de material.

Após o filme de rolo plano 3 passar por vários rolos de guia, ele entra no formador de colar 4, onde é primeiro selado e formado pelo aquecedor de selagem longitudinal 5, sobreposto ou encaixado em um formato cilíndrico. Neste momento, uma porção do material medido pelo dispositivo de medição cai no saco do funil 1 através do tubo de alimentação 2. O aquecedor de selagem transversal 6 sela o fundo do saco enquanto puxa o saco para baixo e sela o saco anterior cheio de material e corta entre os dois sacos para separá-los. O saco acabado 7 cheio de material é separado do equipamento. As ações de cada atuador da máquina podem ser controladas automaticamente por controle mecânico, elétrico, pneumático ou hidráulico.

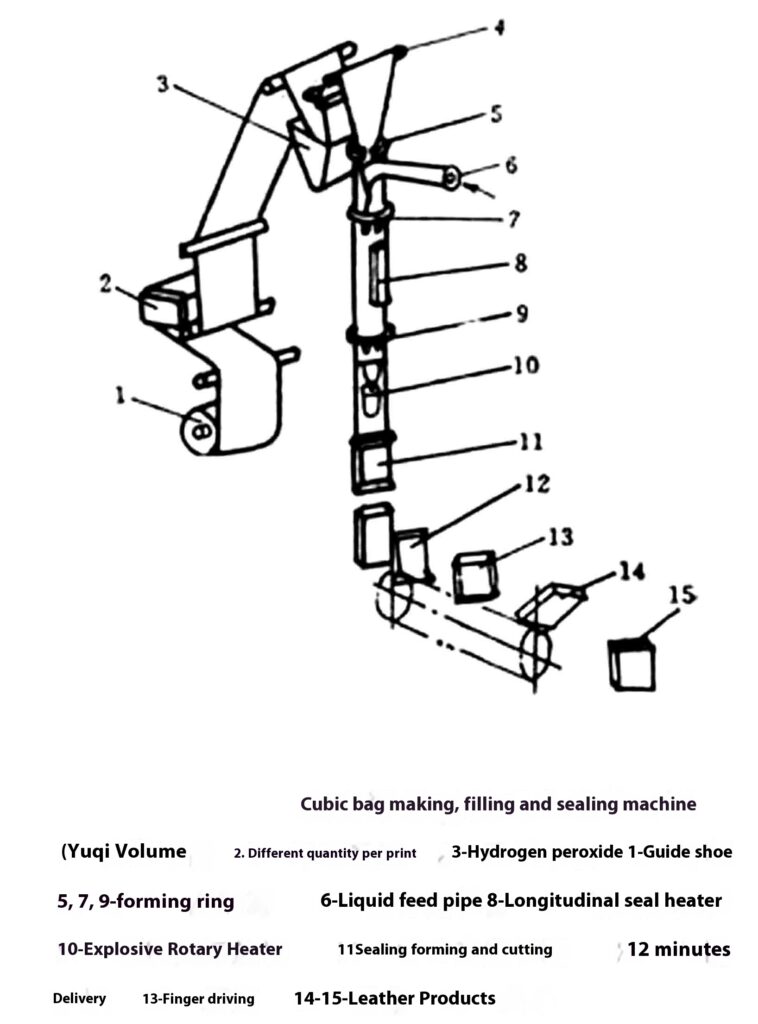

Máquina de envase e selagem para fabricação de sacos de coluna cúbica e torre

Esta máquina é usada principalmente para encher e embalar bebidas líquidas, e o recipiente de embalagem pode ser em formato de torre ou cúbico.

Esta máquina é usada principalmente para encher e embalar bebidas líquidas, e o recipiente de embalagem pode ser em forma de torre ou cúbico. A figura mostra o princípio de funcionamento da máquina de enchimento e selagem de embalagens macias de bebidas cúbicas da Tetra Pak. Após o material de embalagem no rolo de filme plano 1 ser desinfetado pelo dispositivo de impressão 2 (se já houver texto impresso no material de embalagem, ele pode ser omitido) e o tanque de desinfetante de peróxido de hidrogênio 3, ele é guiado para baixo pelo rolo guia 4 e enrolado em um formato cilíndrico sob a ação dos anéis de formação 5 e 7. A costura do saco de embalagem é aquecida pelo ar estéril quando se move para baixo, e o material de embalagem é pressionado em uma costura de vedação longitudinal pelo aquecedor de vedação longitudinal 8 quando passa pelo último anel de formação 9. O material líquido (como suco e leite fresco) é bombeado para o saco de embalagem cilíndrico pelo tubo de alimentação de líquido 6 pela bomba, e o ar quente estéril entra no cilindro do lado de fora do tubo do material e atinge a superfície do líquido. Há também um aquecedor espiral 10 na superfície do líquido, que esteriliza a parede interna do material e forma uma camada de ar estéril na superfície do líquido.

A selagem e o corte horizontais são realizados abaixo da superfície do líquido. Diferentes configurações do dispositivo de selagem horizontal formam diferentes produtos de coluna cúbica e embalagem de torre. No caso de embalagem de torre, os cortadores de selagem horizontal superior e inferior são 900. O espaço é escalonado, e os movimentos para cima e para baixo e de abertura e fechamento são realizados respectivamente para concluir a selagem e o corte horizontais dos itens embalados. Ao embalar em uma coluna cúbica, o saco de material cilíndrico sob a superfície do líquido é puxado para baixo, e a moldagem, selagem e corte são realizados por meio do movimento composto de dois pares de moldes de formação de ângulo reto e a selagem horizontal nos movimentos de abertura e fechamento e para cima e para baixo. O produto semiacabado após o corte cai na corrente transportadora em movimento intermitente. Durante a operação da corrente transportadora, os processos de acabamento, como dobrar asas e dobrar cantos do saco de material, são concluídos e, finalmente, o produto acabado 15 é descarregado da corrente transportadora.

Filmes planos usados para bebidas como suco e leite são geralmente feitos de materiais de filme compostos, como papel encerado-folha de alumínio-polietileno. Antes de ser enrolado em um rolo, a superfície externa do papel encerado foi impressa com instruções de texto e marcas registradas de padrões. Uma caixa de coluna cúbica é apenas um material de filme composto plano, e a superfície superior da caixa é fornecida com um orifício de vedação de alumínio para beber; abra o orifício de vedação de alumínio e insira um canudo para sugar a bebida.

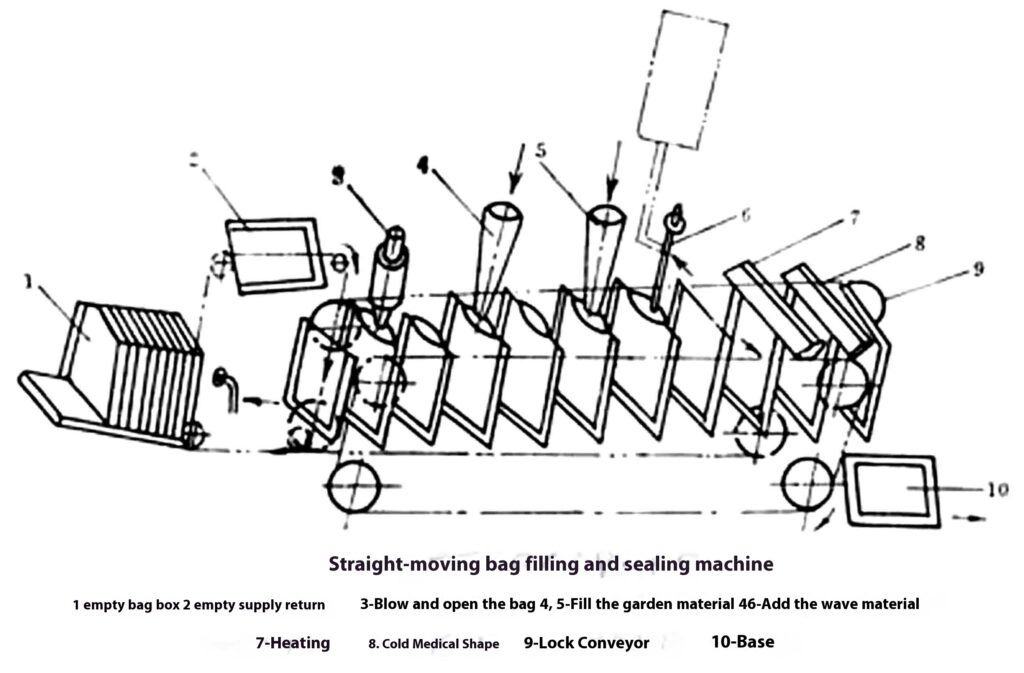

Máquina de enchimento e selagem de sacos de transferência direta

Apenas encha e sele, sem fazer sacos.

Antes de usar a máquina de enchimento e selagem de alimentação de saco, vários sacos vazios pré-processados devem ser empilhados na caixa de saco vazio. Ao trabalhar, um saco vazio é retirado da camada de saco da caixa de saco vazio a cada vez, e o saco vazio é parado em cada estação pela braçadeira da corrente transportadora para concluir cada ação de embalagem.

A máquina de enchimento e selagem de alimentação de saco pode ser dividida em dois tipos de acordo com a rota de caminhada da corrente transportadora: tipo de movimento reto e tipo rotativo. A primeira corrente transportadora move o saco vazio em linha reta, e a última se move de forma rotativa. Mas os princípios de funcionamento dos dois são basicamente os mesmos. A figura mostra o diagrama esquemático da rota do processo da máquina de enchimento e selagem de alimentação de saco de movimento reto. O dispositivo de alimentação de saco consiste em uma cabeça de sucção a vácuo e uma corrente transportadora de alimentação de saco. Quando o saco vazio 2 se move da caixa de saco vazio 1 para a estação de sopro e abertura de saco, com a ajuda da mão de fixação da corrente de trabalho 9, o tubo de ar 3 sopra ar para a boca do saco do saco vazio para abrir a boca do saco. Quando o saco vazio aberto se move para a estação abaixo do funil de material sólido 4 e 5, o saco vazio é preenchido com material, ou o alimentador de líquido 6 injeta material líquido nele. O transportador de corrente 9 é fornecido com uma mão de fixação de uma estrutura especial? Cada par de mãos de fixação prende um saco. O saco cheio de material continua a se mover e é selado pelo aquecedor 7, prensado a frio e moldado, e finalmente a mão de fixação libera o saco, e o produto acabado cai e é descarregado através do dispositivo de transporte de descarga.

A figura mostra um saco vazio para selagem de três lados, e o saco acabado é um tipo de selagem de quatro lados. O material de fabricação do saco é um filme de camada única ou um filme composto. O filme de camada única não é usado porque é difícil pegar e fornecer o saco.

Conclusão

Os tipos de sacos de embalagem e as máquinas de embalagem a vácuo são essenciais para as indústrias alimentícia e farmacêutica, garantindo a qualidade do produto e prolongando a vida útil. Embora vários tipos de sacos estejam disponíveis para atender a diferentes materiais e estéticas, as máquinas de embalagem a vácuo aprimoram o processo de preservação removendo o ar, evitando a oxidação e facilitando a esterilização térmica. A estrutura e os princípios de funcionamento das máquinas de embalagem a vácuo de câmara única e dupla desempenham um papel significativo na simplificação do processo de embalagem, tornando-o mais eficiente, confiável e adequado para uma variedade de produtos. Entender esses métodos de embalagem é essencial para otimizar as operações de embalagem e garantir que os produtos estejam bem protegidos para armazenamento e transporte.