Việc lựa chọn vật liệu đóng gói tối ưu ảnh hưởng trực tiếp đến lợi nhuận, uy tín thương hiệu và dấu chân môi trường của bạn. Hướng dẫn toàn diện này tiết lộ cách cân bằng các đặc tính vật liệu với hệ thống đóng gói tự động – được hỗ trợ bởi 12 năm kinh nghiệm thực tế trong việc tối ưu hóa dây chuyền đóng gói cho hơn 37 ngành công nghiệp. Khám phá cách lựa chọn vật liệu có thể cắt giảm chất thải bằng 40% trong khi tăng tốc độ sản xuất.

Có những loại vật liệu đóng gói nào?

Vật liệu đóng gói được phân loại dựa trên thành phần và mục đích sử dụng. Các loại chính bao gồm:

- Giấy và bìa cứng: Được sử dụng rộng rãi vì khả năng tái chế và phân hủy sinh học, thích hợp cho hộp, thùng các tông và bao bì bảo vệ.

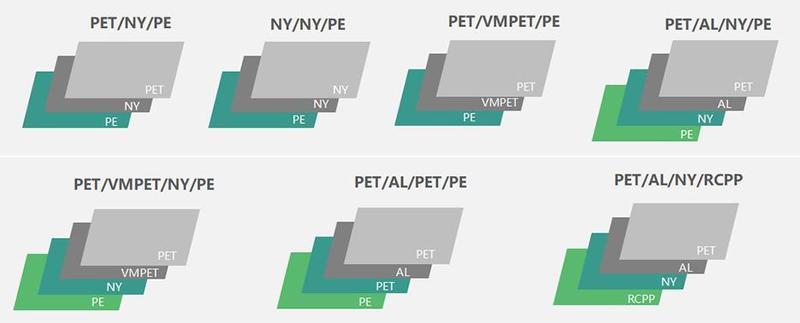

- Nhựa: Đa năng và tiết kiệm chi phí, các loại nhựa như polyethylene (PE), polypropylene (PP) và polyethylene terephthalate (PET) thường được dùng trong chai, túi và màng.

- Thủy tinh: Không phản ứng và không thấm nước, thủy tinh lý tưởng cho đồ uống và dược phẩm nhưng nặng hơn và dễ vỡ hơn.

- Kim loại: Nhôm và thiếc được sử dụng để làm lon và hộp đựng, mang lại độ bền và khả năng tái chế.

- Vật liệu phân hủy sinh học: Các vật liệu như axit polylactic (PLA) và polyhydroxyalkanoate (PHA) có nguồn gốc từ các nguồn tài nguyên tái tạo và có khả năng phân hủy sinh học.

Mỗi vật liệu đều có những ưu điểm và hạn chế riêng, khiến việc lựa chọn vật liệu phải phù hợp với yêu cầu của sản phẩm và mục tiêu phát triển bền vững.

Tại sao máy đóng gói tự động lại quyết định lựa chọn vật liệu?

Hiện đại máy đóng gói dạng đứng (VFFS) và các lớp bọc dòng chảy đòi hỏi các đặc tính vật liệu cụ thể để duy trì thời gian hoạt động 99,9%:

Các yếu tố tương thích quan trọng

| Loại máy | Vật liệu ưa thích | Vật liệu rủi ro |

|---|---|---|

| VFFS điều khiển bằng servo | Màng PET/PE, màng OPP | Giấy dày (>120gsm) |

| Máy đóng gói dòng khí nén | Giấy tráng phủ, màng kim loại | Giấy kraft không tráng phủ |

| Máy tạo hình nhiệt | APET/CPET, tấm PVC | Nhựa sinh học PLA |

Nguyên tắc chung của một kỹ sư đóng gói: “Sổ tay hướng dẫn sử dụng máy sẽ chỉ rõ sân chơi vật liệu của bạn.”

Ví dụ: Một công ty sản xuất đồ ăn nhẹ sử dụng màng PLA phân hủy sinh học đã gặp phải tình trạng kẹt máy 23% cho đến khi chuyển sang hỗn hợp PET/PLA có độ bền kéo tốt hơn. Bài học rút ra là gì? Tính bền vững phải phù hợp với thực tế kỹ thuật.

Giấy, Nhựa và Vật liệu tổng hợp sinh học: Loại nào thực sự chiến thắng về tính bền vững?

Cuộc tranh luận về tính bền vững đòi hỏi phải phân tích vòng đời thay vì các giả định bề nổi:

So sánh dấu chân carbon (trên 1000 đơn vị)

| Vật liệu | Sản xuất CO2 | Năng lượng tái chế | Phân hủy |

|---|---|---|---|

| LDPE nguyên chất | 8,2kg | 1,4kW | Hơn 450 năm |

| PET tái chế | 3,1kg | 0,9kW | Tái sử dụng vô hạn |

| Giấy Kraft | 5,7kg | 2,3kW | 12 tuần |

| Bao bì nấm | 1,8kg | Không có | 3 tuần |

Nguồn: Phân tích chất thải bao bì của EPA năm 2023

Giải pháp mới nổi: Vật liệu lai như giấy/tấm ép PLA cung cấp độ cứng thân thiện với máy với khả năng phân hủy sinh học 94%. Khả năng chống rách đã được kiểm tra: 23N so với 17N đối với giấy nguyên chất.

5 tính chất vật liệu nào ảnh hưởng đến hiệu suất của máy tự động?

- Độ bền kéo

- Tối thiểu 35MPa cho máy đóng gói định hình tốc độ cao

- Ảnh hưởng đến độ chính xác theo dõi phim

- Hệ số ma sát (CoF)

- Lý tưởng 0,2-0,4 để nạp vật liệu mịn

- Lớp phủ silicon làm giảm vấn đề trượt dính

- Ngưỡng niêm phong nhiệt

- Phải phù hợp với nhiệt độ hàm (khoảng 120-200°C)

- Ví dụ: BOPP yêu cầu nhiệt độ niêm phong là 140-160°C

- Độ giãn dài khi đứt

- <5% được ưa chuộng để tạo hình túi chính xác

- Phim căng cần có hệ thống kiểm soát độ căng

- Rào cản độ ẩm

- 0,05 g/m²/ngày đối với bao bì hàng khô

- Lớp nhôm tăng cường khả năng bảo vệ nhưng làm phức tạp quá trình tái chế

Mẹo chuyên nghiệp: Luôn luôn yêu cầu chứng nhận vật liệu dành riêng cho máy từ các nhà cung cấp. Một nhà sản xuất sô cô la hàng đầu đã giảm tỷ lệ rách bao bì từ 12% xuống còn 0,3% bằng cách sử dụng màng phủ chống tĩnh điện.

Cuộc cách mạng vật liệu thông minh: Bao bì chủ động kéo dài thời hạn sử dụng

Vật liệu thế hệ tiếp theo có chức năng kép:

- Chất khử oxy: Màng sắt hấp thụ 99% O₂ trong vòng 24 giờ

- Bộ điều khiển Ethylene: Giấy thấm đất sét làm chậm quá trình chín của trái cây

- Chỉ báo thời gian-nhiệt độ: Mực đổi màu thể hiện độ tươi mới

“Bao bì chủ động không phải là khoa học viễn tưởng – nó đang cắt giảm 10% chất thải thực phẩm toàn cầu ngay lúc này.” – Tạp chí Công nghệ Thực phẩm

Danh sách kiểm tra thực hiện:

✅ Xác nhận khả năng tương thích với máy dò kim loại

✅ Kiểm tra độ ổn định nhiệt cho quy trình hàn kín

✅ Kiểm tra ngưỡng di cư (<10ppm)

Sở thích của người tiêu dùng ảnh hưởng thế nào đến việc lựa chọn vật liệu đóng gói?

Sở thích của người tiêu dùng có tác động đáng kể đến việc lựa chọn vật liệu đóng gói. Một nghiên cứu của Two Sides North America cho thấy 55% người tiêu dùng Anh thích bao bì giấy vì các đặc tính về môi trường của nó, chẳng hạn như khả năng tái chế và khả năng phân hủy.

Sở thích này không chỉ giới hạn ở Vương quốc Anh; trên toàn cầu, nhu cầu về bao bì bền vững đang ngày càng tăng. Theo báo cáo của NielsenIQ, sự chuyển dịch sang các hoạt động kinh doanh thân thiện với môi trường hơn và sở thích thay đổi của người tiêu dùng đang thúc đẩy nhu cầu về bao bì bền vững.

Các công ty lựa chọn bao bì phù hợp với sở thích của người tiêu dùng về tính bền vững có thể nâng cao danh tiếng thương hiệu và thu hút người tiêu dùng có ý thức bảo vệ môi trường.

Lựa chọn tương lai: Vật liệu mới nổi định hình xu hướng năm 2025

| Vật liệu | Lợi thế chính | Sự sẵn sàng của máy |

|---|---|---|

| Lớp phủ Graphene | 200% rào cản độ ẩm mạnh hơn | Yêu cầu hướng dẫn ma sát thấp |

| Sợi nano xenluloza | Có thể ủ tại nhà, chống dầu | Giới hạn ở tốc độ <80m/phút |

| Phim tự chữa lành | Vi nang sửa chữa vết rách 0,2mm | Tương thích với phớt siêu âm |

| Nhựa sinh học có thể lập trình | Phân hủy theo lệnh | Tiêu chuẩn ép nhiệt |

Thông tin chuyên sâu về ngành: Những người áp dụng sớm báo cáo lợi tức đầu tư (ROI) trong 18 tháng cho khoản đầu tư vật liệu thông minh thông qua việc giảm thiểu chất thải.

Những cải tiến trong vật liệu đóng gói bền vững là gì?

Ngành công nghiệp bao bì đang chứng kiến một số giải pháp cải tiến nhằm mục đích giảm tác động đến môi trường:

- Bao bì làm từ rong biển: Các công ty như Sway đang phát triển nhựa sinh học từ rong biển phân hủy sinh học dành cho túi poly thời trang, cung cấp giải pháp thay thế bền vững cho nhựa truyền thống.

- Vật liệu dựa trên sợi nấm: Nấm sợi, cấu trúc rễ của nấm, đang được sử dụng để tạo ra vật liệu đóng gói bền vững có khả năng phân hủy sinh học và ủ phân.

- Lớp phủ phân hủy sinh học: Các công ty khởi nghiệp như Earthodic đang phát triển lớp phủ bảo vệ có thể tái chế hoàn toàn cho bao bì giấy và bìa cứng, thay thế các giải pháp làm từ nhựa hoặc hóa dầu không thể tái chế.

Những cải tiến này phản ánh xu hướng phát triển bền vững rộng hơn của ngành, cung cấp các giải pháp thay thế cho vật liệu đóng gói truyền thống.

Làm thế nào để tích hợp bao bì bền vững vào chiến lược kinh doanh của bạn

Việc tích hợp bao bì bền vững vào chiến lược kinh doanh của bạn bao gồm một số bước chính:

- Đánh giá tác động môi trường: Đánh giá tác động môi trường của vật liệu đóng gói hiện tại của bạn và xác định những lĩnh vực cần cải thiện.

- Khám phá các giải pháp thay thế: Nghiên cứu và xem xét các vật liệu thay thế phù hợp với mục tiêu phát triển bền vững, chẳng hạn như các vật liệu có thể phân hủy sinh học hoặc tái chế.

- Thu hút các bên liên quan: Hợp tác với các nhà cung cấp, khách hàng và chuyên gia trong ngành để phát triển và triển khai các giải pháp đóng gói bền vững.

- Trao đổi những nỗ lực: Truyền đạt rõ ràng các sáng kiến phát triển bền vững của bạn tới người tiêu dùng để nâng cao hình ảnh thương hiệu và đáp ứng mong đợi của người tiêu dùng.

Đừng sợ để hỏi LTC Pack các câu hỏi và yêu cầu tham khảo. Liên hệ với chúng tôi ngay!