Oil pouch packing machines are key to modern manufacturing. They let you package edible oils, lubricants, and industrial fluids efficiently, hygienically, and precisely.

These machines automate forming, filling, and sealing pouches. They keep products intact and cut down on waste and labor costs.

By 2035, the global edible oil market could hit $10.5 billion. For businesses wanting to optimize production and meet changing consumer needs, knowing these systems is key.

How Oil Pouch Packing Machines Work

Modern oil pouch packing machines work in a simple, efficient way:

- Unwind the film: A roll of multi-layered LDPE or nylon film goes into the machine.

- Form the pouch: The film gets shaped into a tube. Then it’s sealed vertically with impulse heating.

- Fill the pouch: An geared pump or piston system puts in oil—accuracy is within ±1%. PLC systems control this.

- Seal and cut: Horizontal seals make individual pouches. Then they’re trimmed and pushed out.

Advanced models have servo motors to adjust speed. They also use IoT sensors to monitor things on real time.

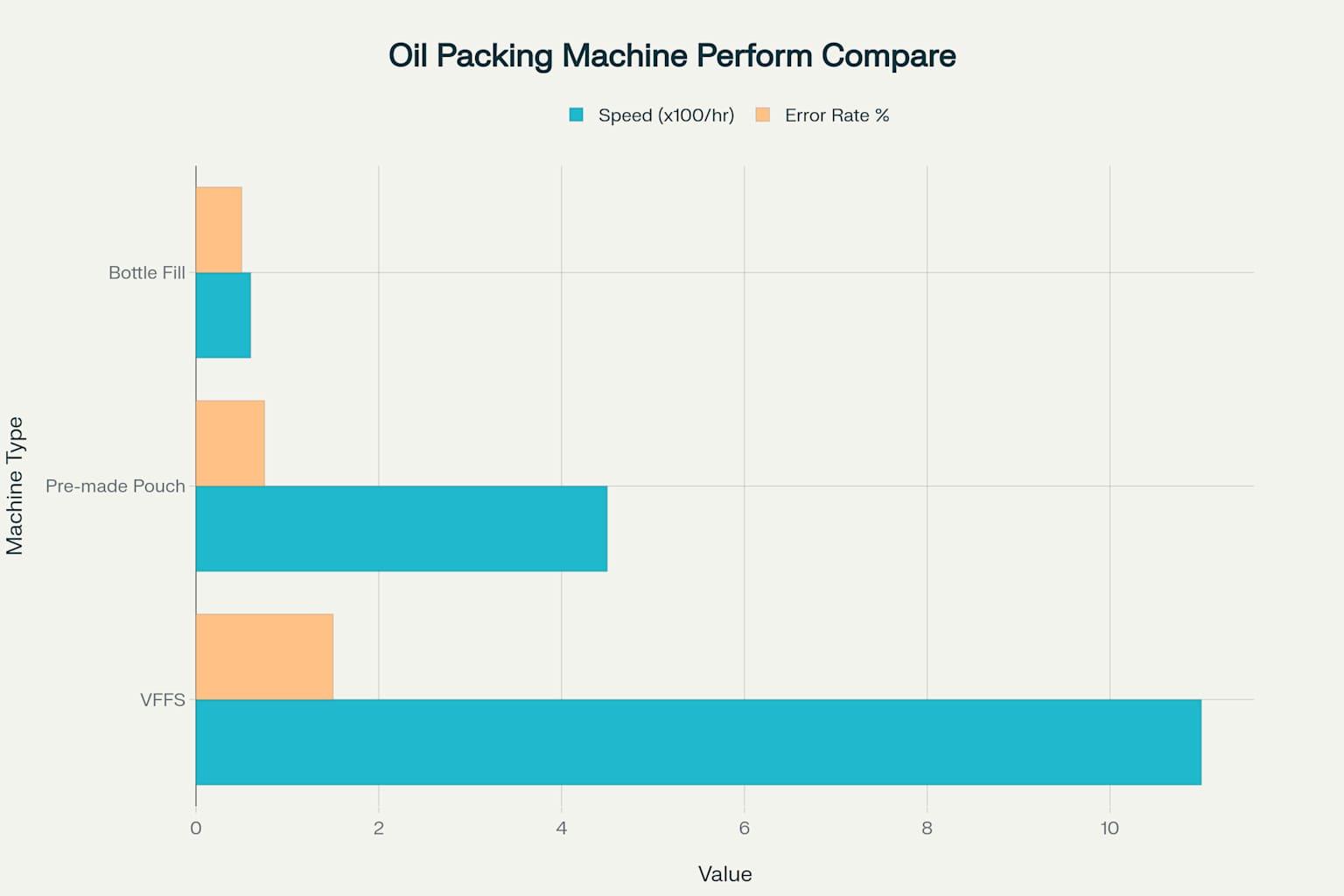

VFFS Packing Machines VS Pre-Made Pouch Filling Machines

VFFS (Vertical Form Fill Seal) Machines

- Speed: 1,000–1,200 pouches per hour

- Accuracy: ±1–2%

- Best for: An high-volume production (200ml–1L pouches)

- Pros: Cheaper film, flexible pouch sizes, compact design.

- Cons: More maintenance, only works with heat-sealable films.

Pre-Made Pouch Filling Machines

- Speed: 300–600 pouches per hour

- Accuracy: ±0.5–1%

- Best for: Premium branding (spouted/zippered pouches)

- Pros: Better print quality, eco-friendly materials, less film waste.

- Cons: More expensive pouches, less size flexibility.

LTC Series Oil Pouch Packing Machine

The LTC Oil Pouch Packing Machine is a leader in automation. It mixes speed with precision:

Features

- PLC control: Lets you program filling volumes (50ml–5L). It also adjusts automatically for thick oils.

- Dual servo motors: Makes 1,500 pouches per hour. Accuracy stays within ±0.5%.

- Multi-layer sealing: Uses impulse and cold sealing to keep pouches from leaking.

- Material compatibility: Works with 80–120 micron LDPE, PET, and biodegradable films.

Applications

- Edible oils (sunflower, olive, palm)

- Industrial lubricants and automotive fluids

- Cosmetics (hair oils, serums)

5 Factors to Consider When Choosing a Machine

- Production volume: VFFS is good for over 10,000 pouches a day. Pre-made systems work better for small batches.

- Pouch design: Think about spouts, zippers, or flat seals.

- Oil viscosity: Use gear pumps for thick oils (≥500 cP). Piston fillers work for light oils.

- Budget: VFFS machines start at $3,500. Pre-made systems cost $8,000–$15,000.

- Sustainability: Pick recyclable films or bag-in-box systems to cut down on plastic.

Conclusion

Choosing the right oil pouch packing machine depends on your production needs, material preferences, and long-term sustainability goals.

VFFS machines are best for high-volume production. Pre-made systems give you more branding options.

Our LTC series fits both needs with its adaptive design. It’s a top pick for manufacturers who want to stay ahead.

Don’t hesitate to contact LTC PACK today.