Förpackningsmaskiner kan grovt delas in i två kategorier:

1. Maskiner som används för att bearbeta förpackningsmaterial och förpackningsbehållare;

2. Maskiner som används för att slutföra förpackningsprocessen. Diskussionen här är begränsad till det senare, det vill säga maskinen som fullbordar förpackningsprocessen kallas för förpackningsmaskin. Definitionen av förpackningsmaskin i den nationella standarden är: "En maskin som fullbordar hela eller delar av förpackningsprocessen. Förpackningsprocessen inkluderar de huvudsakliga förpackningsprocesserna såsom fyllning, inslagning och försegling, såväl som relaterade fram- och bakprocesser såsom rengöring, stapling och demontering. Dessutom inkluderar den även hjälputrustning såsom stämpling och mätning."

Utifrån detta kan förpackningsmaskiner delas in i 8 kategorier: 1. Förpackningsmaskin, 2. Fyllningsmaskin, 3. Förseglingsmaskin, 4. Etikettmaskin, 5. Multifunktionell förpackningsmaskin, 6. Rengörings-, torknings- och steriliseringsmaskin, 7. Behållarmaskin, 8. Förpackningsmekanisk hjälputrustning.

Inslagningsmaskin

Maskinen som slår in produkter med flexibla förpackningsmaterial kallas för förpackningsmaskin. Beroende på de olika inslagningsmetoderna kan den delas in i: ① vikmaskin, ② vridinslagsmaskin, ② sömlindningsmaskin, ① täckinslagningsmaskin, ⑥ lindningsmaskin, ⑧ sträckomslagsmaskin, ⑦ kroppsomslagningsmaskin, ⑧ kroppsinslagningsmaskinen, ⑧ metoden för omslagsmaskinen, etc. inslagningsmaskin.

Påfyllningsmaskin

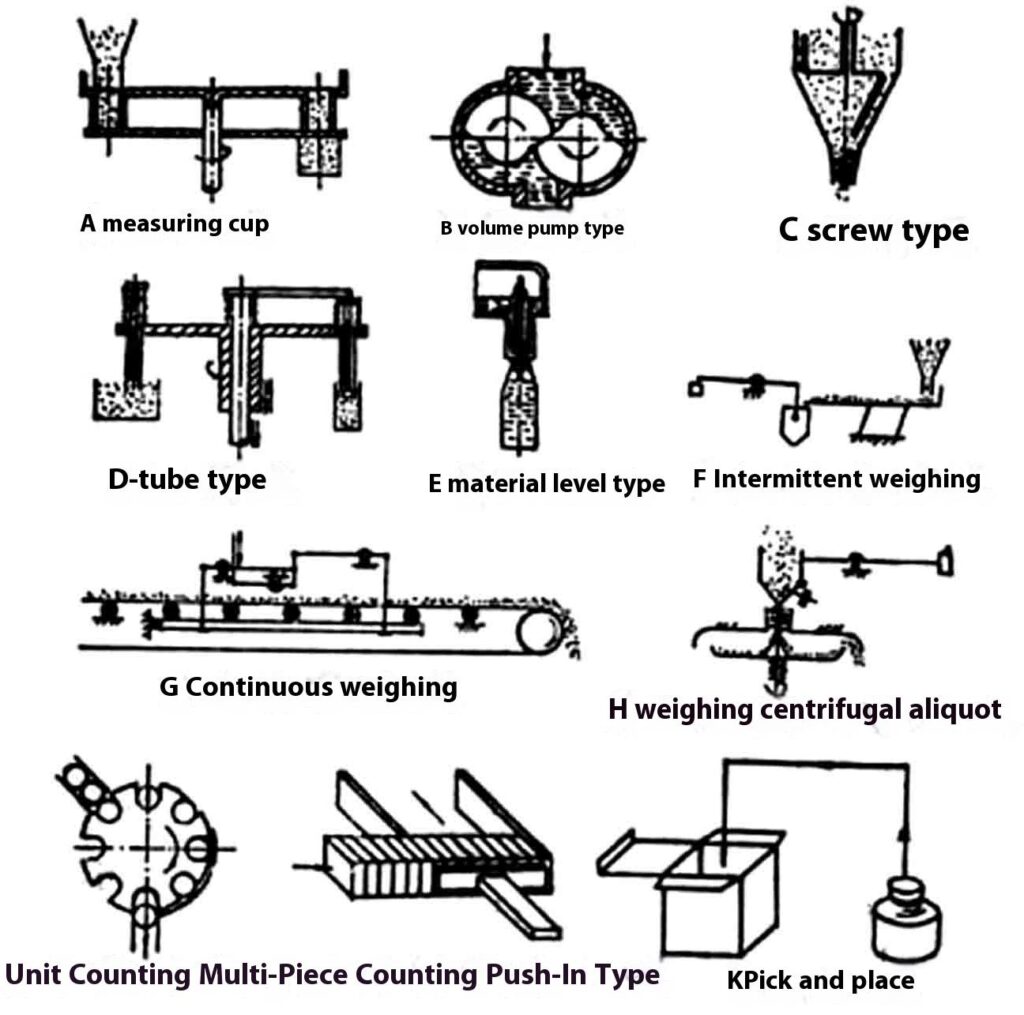

Maskinen som kvantitativt fyller förpackningsmaterialet i förpackningsbehållaren kallas fyllmedel. Enligt de kvantitativa och fyllnadsmetoderna kan den delas in i: 1. Volumetrisk fyllmedel, 2. Vägningsfyllmedel, 3. Räknefyllmedel, 4. Fyllningsmaskin, 5. Gravityfiller, 6. Push-in filler, 7. Pick-and-place filler, etc.

Figuren visar doserings- och fyllningsmetoderna för fyllmedlet

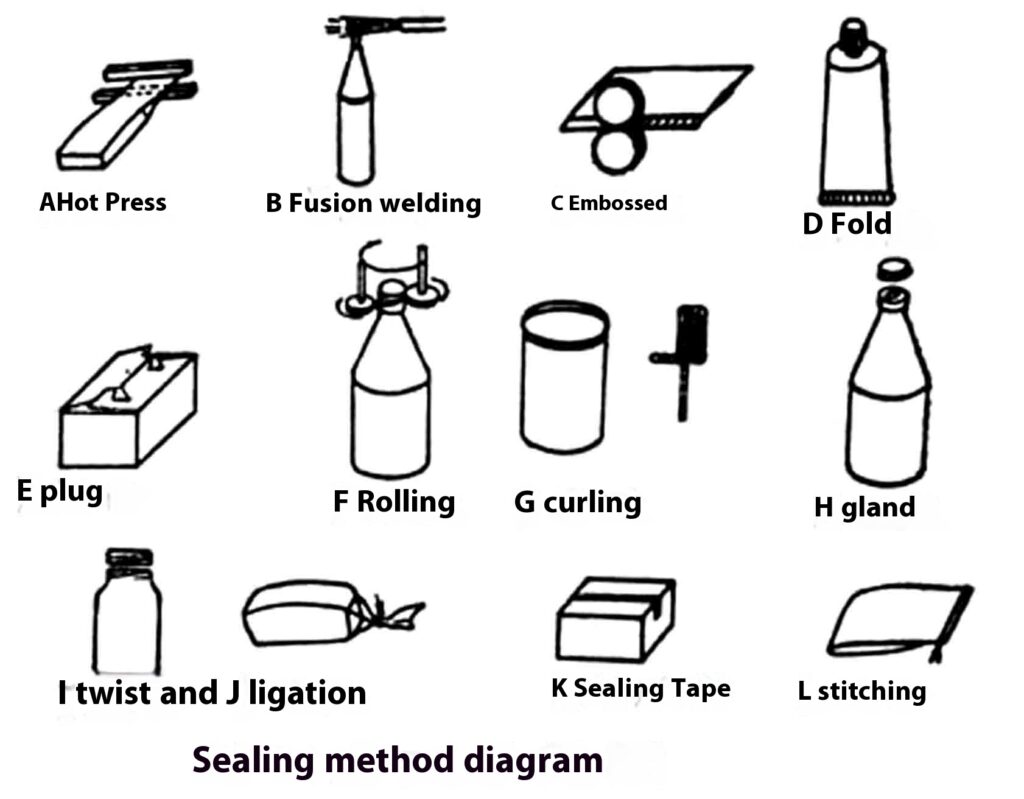

Tätningsmaskin

Maskinen som tätar öppningen på förpackningsbehållaren kallas för förseglingsmaskin. Enligt de olika förseglingsmetoderna kan den delas in i: 1. Varmpressande tätningsmaskin, 2. Svetsförseglingsmaskin, 3. Präglad förseglingsmaskin, 4. Vikningsförseglingsmaskin, 5. Insättningsförseglingsmaskin, 6. Rullförseglingsmaskin, 7. Crimpförseglingsmaskin, 8. Pressförseglingsmaskin, - 9.-segling. maskin, 11. Tejpförseglingsmaskin, 12. Suturförseglingsmaskin, etc.; figuren är ett schematiskt diagram över förseglingsmetoden för förseglingsmaskinen.

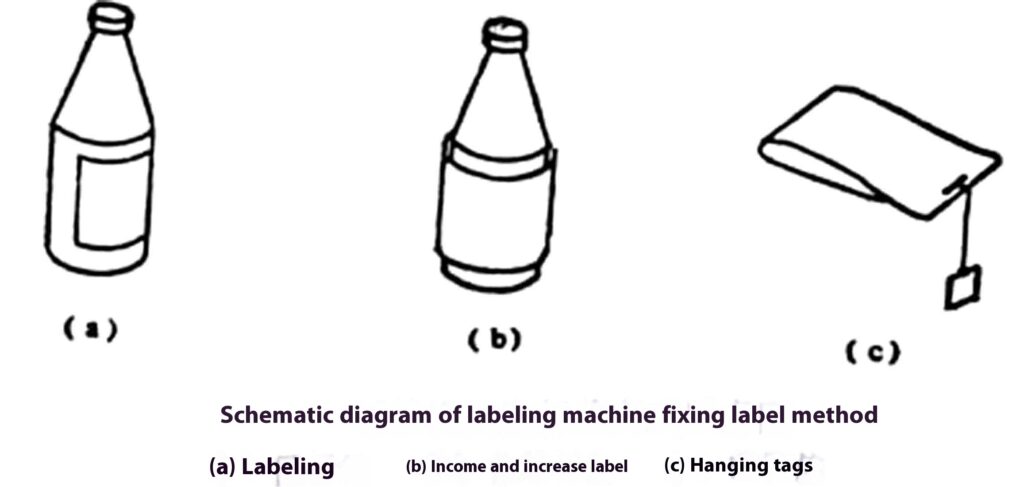

Märkningsmaskin

Maskinen som fäster eller sätter in etiketter på produkten kallas etiketteringsmaskin. Beroende på de olika sätten att fästa etiketter på kan den delas in i: 1. Etikettmaskin, 2. Krympetikettmaskin, 3. Upphängningsetiketteringsmaskin, 4. Spikningsetiketteringsmaskin, 5. Insättningsetiketteringsmaskin etc. Figuren är ett schematiskt diagram över etikettmaskinens fasta etiketteringsmetod;

Övriga förpackningsmaskiner

Övrigt avser andra förpackningsmaskiner än de fyra första typerna:

Multifunktionell förpackningsmaskin

Maskinen som kan genomföra mer än två förpackningsprocesser kallas en multifunktionell förpackningsmaskin. I allmänhet är de namngivna efter den förpackning de kan genomföra. De viktigaste är: 1. Fyllnings- och förseglingsmaskin, 2. Formnings-fyllnings-förseglingsmaskin (för att forma förpackningsmaterial), 3. Formning-fyllnings-förseglingsmaskin (för att forma prefabricerade förpackningsbehållare), 4. Vakuumförpackningsmaskin (fyllning-dammsugning-försegling); 5. Uppblåsbar förpackningsmaskin (fyllning-uppblåsning-försegling), 6. Inslagnings- och etiketteringsmaskin, etc.

Rengöring, sterilisering och torkmaskin

Maskiner som rengör, steriliserar och torkar förpackningsbehållare före förpackning eller förpackade produkter efter förpackning kallas rengöringsmaskiner, steriliseringsmaskiner och torkmaskiner. Till denna kategori av maskiner hör till exempel flasktvättmaskiner, burktvättmaskiner, spraysteriliseringsmaskiner, ångsteriliseringsmaskiner, ultravioletta steriliseringsmaskiner, varmluftstorkar, infraröda torktumlare etc. som vanligtvis används inom lätt industri. Om maskinen har flera funktioner kan den namnges genom att kombinera dess funktioner, såsom rengöring-torkmaskin, sterilisering-torkmaskin, rengöring-sterilisering-torkmaskin

Containerizer

En maskin som packar flera enhetspaket tillsammans kallas containerizer. Den kan namnges enligt dess containeriseringsmetod, såsom: 1. bandningsmaskin, 2. bindningsmaskin, 3. kompressionspress, 4. packningsmaskin, etc.

Förpackning av extra maskiner och utrustning

Alla maskiner och utrustningar som inte kan ingå i ovanstående 7 poster men som är nödvändiga för att slutföra förpackningsprocessen kan kallas förpackningshjälpmaskiner och -utrustning. Till exempel transportanordningar, staplingsbord, mätmaskiner; lådöppnare, limapplikatorer, skrivare, inspektionsmaskiner m.m.

Förutom klassificeringen av förpackningsmaskiner huvudsakligen baserad på maskinens förpackningsfunktion som nämnts ovan, kan de ibland klassificeras ytterligare efter graden av automatisering eller användningsomfång.

Till exempel kan en maskin som använder manuell matning av förpackningsmaterial eller avlägsnande av förpackade produkter men automatiskt kan fullfölja andra förpackningsoperationer kallas en halvautomatisk förpackningsmaskin; en maskin som automatiskt slutför matning, förpackning och färdig produktproduktion kallas en automatisk förpackningsmaskin.

En förpackningsmaskin som endast kan förpacka produkter av en viss form, specifikation och storlek kallas en speciell förpackningsmaskin; en förpackningsmaskin som kan förpacka produkter av två eller flera olika former, specifikationer och storlekar kallas en förpackningsmaskin för flera ändamål; en förpackningsmaskin som kan förpacka produkter av vilken form, specifikation och storlek som helst inom ett visst intervall kallas en allmän förpackningsmaskin.

Tveka inte att kontakta LTC-paket Nu.