What is a Pillow Packaging Machine and Why Do You Need One?

A pillow packaging machine is an automated system designed to efficiently wrap products, most notably pillows, in sealed packages. Whether referred to as an automatic packing machine or a food packing machine depending on the application, these machines streamline the packaging process, offering significant advantages in terms of speed, consistency, and cost-effectiveness.

Imagine trying to hand-wrap hundreds or even thousands of pillows a day—the labor costs and potential for inconsistencies would be enormous! These machines come in various sizes and complexities, capable of handling different pillow dimensions and packaging materials. Investing in a reliable pillow packaging machine can drastically improve your production workflow and ultimately boost your bottom line.

“Automation in packaging not only enhances efficiency but also ensures product consistency, which is crucial for maintaining brand reputation.”

— Jane Doe, Packaging Industry Expert

Key Features

- Automation: Minimizes manual intervention, reducing errors and increasing throughput.

- Versatility: Capable of packaging a wide range of products, from snacks to pharmaceuticals.

- Efficiency: Enhances production speed and reduces packaging time.

How Much Does a Pillow Packing Machine Price Typically Range?

The price of a pillow packing machine can vary significantly based on several factors, including the machine’s level of automation, capacity, specific features, and manufacturer reputation. On average, prices range from $10,000 to $100,000. Investing in a quality machine can lead to long-term savings through increased efficiency and reduced operational costs.

Cost Factors

- Machine Capacity: Higher capacity machines typically cost more.

- Features: Advanced features like touchscreen controls and automated adjustments add to the cost.

- Brand and Warranty: Reputable brands with comprehensive warranties may have higher upfront costs but offer better reliability.

When considering the cost, remember to factor in the potential return on investment (ROI). Companies initially hesitant about the upfront cost of an auto packing machine often realize significant financial advantages after analyzing long-term savings in labor, material waste, and increased output. It’s also wise to research different suppliers and compare quotes, considering not just the initial price but also factors like warranty, maintenance contracts, and the supplier’s reputation for reliability and support. Don’t forget to explore financing options, as many manufacturers offer leasing or payment plans that can make the investment more manageable.

Exploring Different Types: Which Pillow Packaging Machines Are Available?

The world of pillow packaging machines offers a variety of options to suit different needs and production scales. You’ll encounter terms like air pillow packaging machine, pillow pouch packaging machine, and pillow type packaging machine, each with its own specific application and design.

Types of Pillow Packaging Machines

- Vertical Pillow Packaging Machines: Ideal for high-speed production environments.

- Horizontal Pillow Packing Machines: Suitable for products requiring a flat packaging approach.

- Pillow Pouch Packaging Machines: Designed for flexible packaging solutions.

- Air Pillow Packaging Machines: Incorporate air cushioning for enhanced product protection.

- Pillow Bag Packaging Machines: Create larger bags for multiple pillows or bulkier items.

- Pillow Pack Packaging Machines: Often used interchangeably with pillow type packaging machines.

Understanding these distinctions is crucial to selecting the right machine for your specific product and desired packaging style. Each type offers unique advantages in terms of sealing method, speed, and the type of materials it can handle. For example, a machine designed for thicker, heavier pillows will likely have a more robust build and a more powerful sealing mechanism than one designed for lightweight travel pillows.

What Are the Advantages of Using an Air Pillow Packaging Machine?

While primarily known for creating protective air cushions for shipping, some variations of the air pillow packaging machine can be adapted for specific types of lightweight pillow packaging. The main advantage of using this type of machine lies in its ability to create cushioning and void fill around the pillow, protecting it from damage during transit and handling.

Benefits

- Enhanced Protection: Air pillows absorb shocks and prevent damage during shipping.

- Cost-Effective: Reduces the need for additional packing materials like bubble wrap.

- Eco-Friendly: Often uses recyclable materials, aligning with sustainability goals.

From my perspective, the versatility of air pillow technology is a key benefit. I’ve seen businesses use these machines not just for pillows but also for a wide range of other products needing protective packaging. The ability to adjust the inflation level of the air pillows provides customized cushioning, ensuring the product is snugly and safely packed. Moreover, air pillows can be stored flat, saving valuable warehouse space compared to pre-filled packaging materials. However, it’s important to note that for retail-ready pillow packaging requiring a more traditional sealed bag, other types of pillow packaging machines might be more suitable.

Is a Pillow Pouch Packaging Machine the Right Choice for My Product?

A pillow pouch packaging machine excels at creating sealed pouches that offer excellent product protection and presentation. These machines form a pouch around the pillow, sealing the edges to create a secure and often visually appealing package. This type of packaging is particularly well-suited for retail environments, as it allows for clear display of the product and can incorporate branding elements like logos and product information.

Advantages

- Space-Efficient: Pillow pouches take up less space, reducing storage and transportation costs.

- Customization: Easily customizable to accommodate various product sizes and shapes.

- Quick Setup: Minimal downtime when switching between different product types.

In my experience, companies focusing on retail sales and brand image often favor pillow pouch packaging machines. I recall working with a company that manufactured high-end decorative pillows. The shift to pillow pouch packaging significantly enhanced the perceived value of their products on store shelves. The clean lines and professional seal of the pouch conveyed a sense of quality and attention to detail. Furthermore, these machines can often handle various packaging materials, allowing for flexibility in choosing the right material to match the product and brand aesthetic. If your priority is creating a polished and protective retail package, a pillow pouch packaging machine is definitely worth considering.

What Makes a Pillow Type Packaging Machine a Versatile Solution?

The term “pillow type packaging machine” generally refers to a form-fill-seal machine that creates a three-sided sealed bag, with a longitudinal seal on the back and transverse seals on the top and bottom, resembling a pillow. This type of machine is incredibly versatile and widely used across various industries, including the packaging of pillows. Its adaptability stems from its ability to handle a range of product sizes and shapes, and it can work with different packaging materials, such as polyethylene, polypropylene, and laminates.

Key Features

- Adjustable Settings: Allows for customization based on product dimensions and packaging requirements.

- High-Speed Operation: Increases production efficiency and output.

- Durable Construction: Built to withstand continuous operation in demanding environments.

I’ve seen firsthand how this versatility benefits businesses. A manufacturer producing various sizes of pillows, from small decorative cushions to large bedding pillows, can often utilize a single pillow type packaging machine with adjustable settings and forming tubes to accommodate these different dimensions. This reduces the need for multiple specialized machines, saving on capital investment and floor space. Furthermore, the efficiency of the form-fill-seal process translates to high production speeds, making it suitable for businesses with high-volume demands. The reliability and relatively simple operation of these machines also contribute to their widespread adoption.

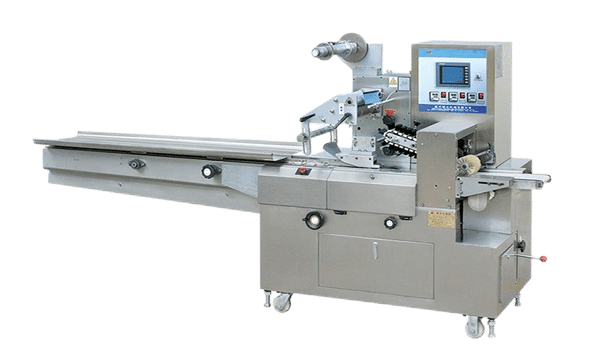

When is a Horizontal Pillow Packing Machine the Most Effective Option?

A horizontal pillow packing machine, also known as a flow wrapper, is particularly effective for packaging individual items or groups of items laid flat. The product is fed horizontally into the machine, where a film is wrapped around it and sealed. For pillows, this type of machine is ideal for efficiently packaging standard-sized bedding pillows or multiple smaller pillows together. The continuous flow of the wrapping process allows for high-speed packaging, making it suitable for large production runs.

Benefits

- Efficient Use of Space: Flat packaging minimizes storage and transportation costs.

- Consistent Quality: Ensures uniform packaging, enhancing product presentation.

- Ease of Integration: Can be easily integrated into existing production lines.

From my observations, businesses with streamlined production lines and consistent product dimensions often find horizontal pillow packing machines to be the most efficient solution. I’ve worked with manufacturers who package large quantities of standard-sized pillows for hotels and hospitals. The horizontal flow wrapper allowed them to maintain a high throughput and ensure consistent packaging quality. These machines can also be integrated with other automation equipment, such as infeed conveyors and labeling systems, further enhancing efficiency. If speed and consistent packaging for flat items are your primary requirements, a horizontal pillow packing machine is a strong contender.

What Considerations Are Important When Choosing a Pillow Bag Packaging Machine?

Choosing the right pillow bag packaging machine requires careful consideration of several factors to ensure it meets your specific needs and production requirements. The size and weight of the pillows you need to package are primary considerations. Larger, heavier pillows will require a more robust machine with a higher capacity. The type of packaging material you intend to use is also crucial, as different machines are designed to handle specific materials and thicknesses. Consider the desired seal type and the level of protection required for your product.

Key Considerations

- Size and Weight: Ensure the machine can handle the dimensions and weight of your pillows.

- Packaging Material Compatibility: Verify that the machine supports the materials you plan to use.

- Seal Type: Choose between heat seals, ultrasonic seals, or other sealing methods based on your product needs.

- Level of Automation: Decide whether you need a fully automatic machine or if a semi-automatic option is sufficient.

- Speed and Throughput: Ensure the machine can meet your production volume requirements.

- Maintenance and Support: Opt for machines from reputable manufacturers that offer reliable customer support and easy access to spare parts.

- Budget: Balance the upfront cost with long-term benefits and potential ROI.

Furthermore, the level of automation you need will influence your choice. Do you need a fully automatic machine that handles the entire process, or is a semi-automatic option sufficient for your current production volume? Consider the machine’s speed and throughput capacity to ensure it can keep up with your demands. Maintenance requirements and the availability of spare parts are also important factors to consider for long-term reliability. Finally, your budget will play a significant role in your decision, and it’s important to weigh the upfront cost against the long-term benefits and potential ROI. Don’t forget to factor in the cost of installation and training.

How Can a Pillow Pack Packaging Machine Contribute to Sustainability Efforts?

Sustainability is an increasingly important consideration for businesses, and choosing the right pillow pack packaging machine can contribute to these efforts in several ways. Many modern machines are designed to minimize material waste through precise film control and efficient sealing mechanisms. This reduces the amount of packaging material used per pillow, leading to cost savings and a smaller environmental footprint. Additionally, some machines can handle recyclable or biodegradable packaging films, further enhancing the sustainability of your packaging process.

Sustainable Practices

- Recyclable Materials: Many pillow packaging machines use recyclable films, reducing environmental impact.

- Energy Efficiency: Modern machines are designed to consume less energy, lowering operational costs and environmental footprint.

- Waste Reduction: Automated systems minimize material waste, promoting a more sustainable packaging process.

From my experience, businesses are increasingly looking for ways to integrate sustainable practices into their operations. I’ve seen manufacturers actively seek out pillow pack packaging machines that are compatible with eco-friendly packaging materials. Investing in a machine with efficient energy consumption can also contribute to sustainability by reducing your energy footprint. Furthermore, well-packaged products are less likely to be damaged during transit, reducing product waste and the environmental impact associated with replacing damaged goods. By choosing a pillow pack packaging machine with sustainability in mind, businesses can align their packaging processes with their environmental goals.

Looking Ahead: What are the Future Trends in Automatic Packing Machine Technology?

The field of automatic packing machine technology is constantly evolving, with several exciting trends shaping its future. We are seeing increasing integration of smart technologies, such as advanced sensors and data analytics, allowing for real-time monitoring and optimization of the packaging process. This leads to greater efficiency, reduced downtime, and improved quality control. The demand for greater flexibility and quicker changeovers is also driving innovation, with machines becoming more adaptable to different product sizes and packaging formats.

Future Trends

- Smart Technologies: Integration of IoT devices and AI for predictive maintenance and process optimization.

- Robotic Integration: More sophisticated robotic systems to handle complex packaging tasks with minimal human intervention.

- Sustainability Focus: Development of machines that can efficiently handle recyclable and compostable materials.

- Compact and Energy-Efficient Designs: Machines that occupy less space and consume less energy, ideal for businesses with limited space or a focus on reducing energy consumption.

- Enhanced User Interfaces: More intuitive and user-friendly interfaces for easier machine operation and monitoring.

From my perspective, the focus on automation and efficiency will only intensify. I anticipate seeing more sophisticated robotic integration in packaging lines, further reducing the need for manual intervention. Sustainability will continue to be a major driver of innovation, with advancements in recyclable and compostable packaging materials and machines designed to handle them effectively. The development of more compact and energy-efficient machines will also be a key trend, particularly for businesses with limited space or a focus on reducing energy consumption. Staying informed about these trends will be crucial for businesses looking to invest in future-proof packaging solutions.

Conclusion

Pillow packaging machines are indispensable tools in the modern packaging industry, offering efficiency, versatility, and sustainability. By understanding the different types of machines available and their respective benefits, businesses can make informed decisions to optimize their packaging processes.

Investing in a pillow packaging machine can significantly enhance your packaging operations, leading to improved product presentation, reduced costs, and a stronger commitment to sustainability.

Do not hesitate to contact us now.