Ever wondered how those little single-serving packets of sugar, shampoo, or even ketchup are made? This article dives into the fascinating world of sachet packaging machines, focusing on the clever mini pouch packing machine. We’ll explore why these compact powerhouses are so important, how they work, and even touch upon how they can contribute to a more recyclable and sustainable future. If you’re curious about efficient packaging solutions and how they’re making a difference, then you’ve come to the right place!

Looking for a Sachet Machine for Sale? What You Need to Know

So, you’re in the market for a sachet machine for sale? That’s fantastic! These machines are real workhorses, especially the smaller versions we’re focusing on. Before you jump in, it’s important to understand what to look for. Consider the types of products you want to package. Are they liquids, powders, or granules? The machine’s capabilities will depend on this. Think about the volume you need to produce. A mini sachet pouch packing solution might be perfect for smaller batches or startup businesses. Don’t forget to factor in the cost of operation and maintenance. Finding the right balance between price and performance is key to making a smart investment.

What Exactly Is a Mini Sachet Pouch Packing Machine?

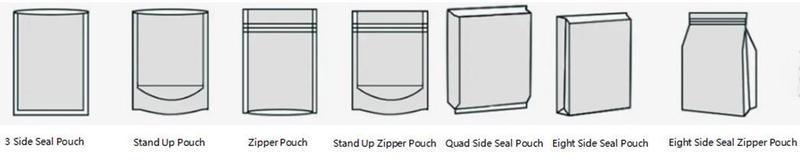

Imagine a machine that can automatically take a roll of packaging film, form it into a tiny pouch, fill it with a precise amount of product, and then seal it all up – that’s essentially what a mini sachet pouch packing machine does! Think of it like a miniature factory line, all contained in a relatively small footprint. These machines are designed for efficiency and precision, ensuring that each sachet pouch packing is consistent and meets the required standards. They are incredibly versatile and can handle a wide range of products, from food and beverages to cosmetics and pharmaceuticals.

Why are Mini Packing Machines So Popular?

Have you noticed how many products come in individual packets these days? There’s a good reason for that, and mini packing machines play a big role. These machines are popular because they offer a cost-effective and efficient way to package products. They are perfect for portion control, preventing waste, and offering convenience to consumers. For businesses, a mini packing machine can be a game-changer, especially for startups or companies with limited space. They are often easier to operate and maintain compared to larger, more complex systems. Plus, the ability to quickly and easily package products in single-serve portions opens up new market opportunities.

Can These Machines Fill Liquid Bottles? Exploring Versatility

While primarily designed for flat pouches, some advanced mini sachet pouch packing machine models can indeed handle liquids! You might be thinking, “But it’s a pouch machine!” That’s true, but the technology is evolving. Some mini packing machine variations can be adapted or configured to fill small bottles or vials as well. Think about those tiny hotel shampoo bottles – often, the filling process is similar to filling a liquid sachet. However, if your primary need is filling larger liquid bottles, you’ll likely be looking at dedicated liquid bottle filling machines, which are specifically engineered for that purpose.

What Kind of Products are Ideal for a Mini Sachet Packing Machine?

Think small and convenient! A mini sachet packing machine excels at packaging products in single-serving sizes. Imagine those individual sugar packets you get with your coffee, or the little sachets of spices in your instant noodle soup. Powders, granules, and small amounts of liquids are all perfect candidates. This includes things like instant coffee, tea, salt, pepper, ketchup, mustard, mayonnaise, shampoo, conditioner, lotions, and even certain types of medications. The key is that the product needs to be easily flowable or dispensable in small quantities. The pouch packing machine ensures each packet is accurately filled and securely sealed, maintaining the product’s quality and freshness.

Sustainability and Recyclable Materials: A Key Focus

We can’t talk about packaging without considering the environment. The good news is that the sachet packaging machine industry is increasingly focusing on sustainability. Manufacturers are developing machines that can handle recyclable packaging materials. Imagine using films made from plant-based sources or easily recyclable plastics. This shift is crucial in reducing plastic waste. While single-serve packets might seem like they generate a lot of trash, advancements in material science and recycling infrastructure are making a difference. Choosing a pouch packing machine that can work with eco-friendly materials is a responsible step towards a greener future.

How Much Does a Mini Sachet Pouch Packing Machine Cost?

The cost of a mini sachet pouch packing machine can vary quite a bit depending on several factors. Think of it like buying a car – different models have different features and price points. Factors that influence the price include the machine’s speed, automation level, the types of materials it can handle, and any additional features like date coding or nitrogen flushing. A basic, entry-level mini packing machine might be relatively affordable, while more sophisticated models with advanced capabilities will have a higher price tag. It’s essential to get quotes from different suppliers and carefully consider your budget and production needs before making a decision.

Maintaining Your Mini Packing Machine for Longevity

Just like any piece of machinery, a mini packing machine requires regular maintenance to keep it running smoothly and efficiently. Think of it like taking care of your bicycle – you need to oil the chain and check the tires. Regular cleaning is crucial to prevent product buildup and ensure hygienic operation. Following the manufacturer’s recommended maintenance schedule is essential. This might include lubricating moving parts, checking belts and seals, and inspecting electrical connections. Proper maintenance not only extends the lifespan of your pouch packing machine but also helps prevent costly breakdowns and ensures consistent performance.

Future Trends in Mini Sachet Pouch Packing Technology

The world of sachet packaging machines is constantly evolving. Imagine machines that are even more compact, faster, and easier to use. We’re seeing advancements in automation, with some machines now incorporating robotics for tasks like feeding and unloading. The focus on sustainability will continue to drive innovation in packaging materials and machine design. Think about even more efficient use of materials and the ability to handle compostable films. The integration of smart technology, such as remote monitoring and diagnostics, is also on the rise, allowing for predictive maintenance and optimized performance of your mini sachet pouch packing.

Here’s a quick look at some key specifications for different types of mini sachet pouch packing machines:

| Feature | Basic Model | Intermediate Model | Advanced Model |

|---|---|---|---|

| Speed (pouches/min) | 20-40 | 40-80 | 80-120 |

| Product Types | Powders, granules | Powders, granules, liquids | Powders, granules, liquids, pastes |

| Automation Level | Semi-automatic | Semi-automatic with options | Fully automatic |

| Packaging Material | Heat-sealable films | Heat-sealable & some recyclable films | Wide range, including recyclable & compostable |

| Footprint | Small | Medium | Medium to Large |

| Price Range | $5,000 – $15,000 | $15,000 – $30,000 | $30,000 + |

“Investing in a mini sachet pouch packing machine was a game-changer for our small business. It allowed us to efficiently package our products and reach a wider customer base with convenient single-serving options.” – Local Food Producer

- Remember that sachet packaging machines, especially the mini versions, are designed for efficient single-serving packaging.

- Consider the type of product you need to package when choosing a mini pouch packing machine.

- Sustainability is a growing focus, with machines capable of handling recyclable materials.

- Proper maintenance is key to ensuring the longevity of your pouch packing machine.

- The technology in mini packing machine is constantly improving, offering more advanced features.

For those interested in larger scale operations, exploring options for liquid filling solutions might be beneficial. If you’re looking for a machine specifically for bottling, research into various liquid bottle filling machines is recommended. Thinking about expanding your production line? Consider how packaging automation could streamline your processes. To find reliable suppliers, searching for a “sachet machine for sale” online will yield numerous results. Finally, remember that choosing the right materials is crucial for both product protection and sustainable packaging solutions.