導入

袋詰め機は現代の包装作業に欠かせない存在であり、さまざまな業界の幅広い製品を効率的かつ正確に包装することを可能にします。これらの機械は、さまざまなサイズや素材の袋に一貫して充填することを保証します。包装プロセスを最適化するには、その種類、機能、用途を総合的に理解することが不可欠です。

さまざまな業界への応用

袋充填機はさまざまな分野で広く使用されています。

食品・飲料:砂糖、小麦粉、米などの乾燥原料の包装に。

医薬品および化学: 錠剤、カプセル、粉末の袋詰め用。

その他の産業: ペットフード、農産物、工業資材などを含む。

袋充填機の種類

袋充填機は主に容積式と重量式の 2 種類に分類されます。

容積測定機

これらの機械は計量カップまたはホッパーを使用して、各バッグに一定量の材料を分配します。粉末や粒状製品などの流動性の高い材料に最適です。

重量測定機

これらの機械は、各袋に充填される材料の重量をセンサーで測定します。密度が異なる材料に適しており、正確な重量管理が必要です。

袋詰め機の最新機能

高度な袋充填機には、さまざまな機能とテクノロジーが搭載されています。

- 自動バッグ処理: スムーズで効率的な操作のために、袋を搬送、蓄積、インデックス付けするシステム。

- 製品供給システム: 材料の充填が一貫して均一であることを確認します。

- 充填精度管理: センサーとフィードバック機構により精度が向上します。

- 袋の密封と閉鎖: 自動化システムにより、安全で改ざん防止のパッケージが保証されます。

適切なマシンの選択

袋詰め機を購入する際は、その機械が特定のニーズを満たし、一貫した結果を生み出すことを保証するために、いくつかの要素を考慮することが重要です。袋詰め機を選択する際に考慮すべき重要な側面は次のとおりです。

生産能力

最初に考慮すべき要素は、袋詰め機の生産能力です。これにより、生産要件に応じて、1 分または 1 時間あたりに充填できる袋の数が決まります。充填する予定の製品のサイズと重量、および希望する出力を考慮してください。大量生産が予想される場合は、より強力で容量の大きい機械が必要になる場合があります。

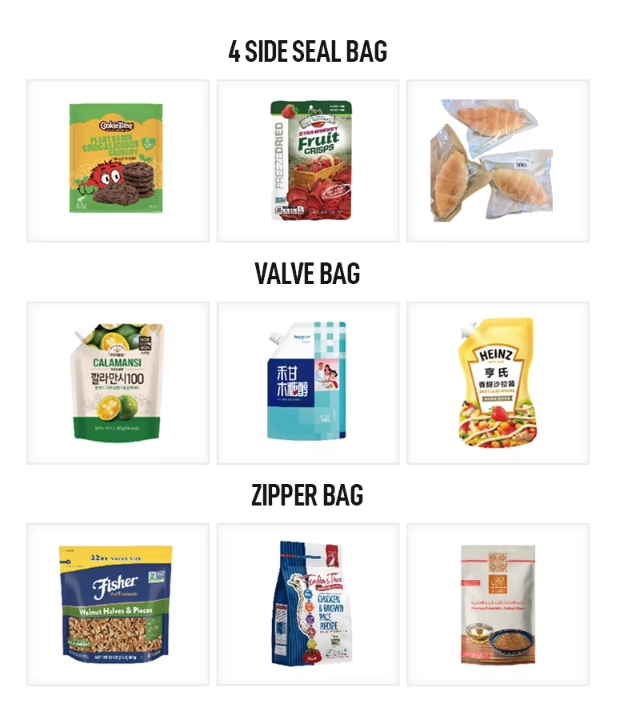

バッグ素材の互換性

袋詰め機が、必要な袋の素材の種類に対応できることを確認してください。ポリエチレン袋用に設計された機械もあれば、紙袋や織り袋に適した機械もあります。機械が、希望する袋の素材に問題なく対応できることを確認することが重要です。

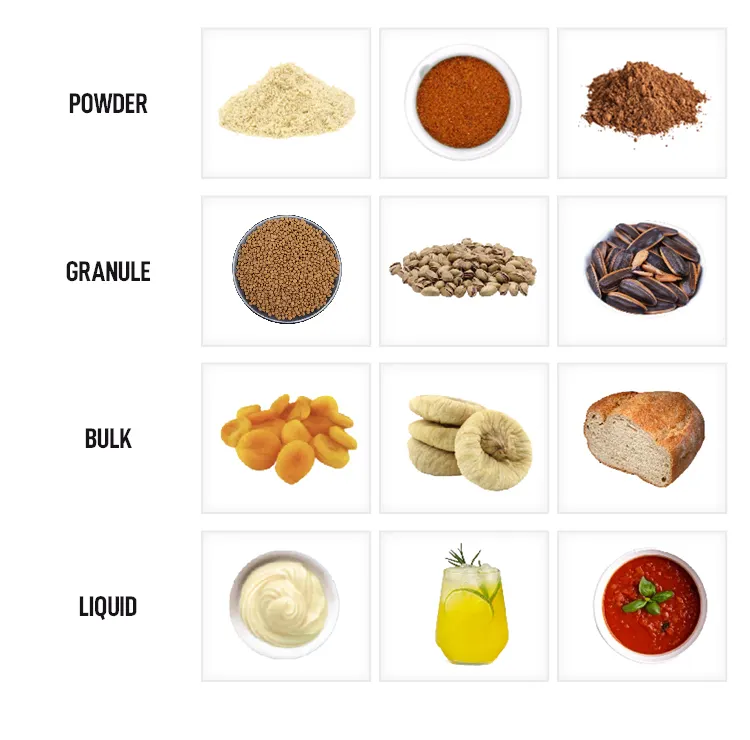

製品タイプ

充填したい製品の種類も、袋充填機の選択に影響します。乾燥粉末や顆粒に適した機械もあれば、液体や粘性物質向けに設計された機械もあります。製品の流動特性と粘稠度を考慮して、効果的に処理できる機械を選択してください。

安全機能

袋詰め機を選ぶ際は、安全性を最優先に考えてください。インターロック、ガード、緊急停止ボタンなどの機能を備えた機械を探し、オペレーターを怪我から守りましょう。さらに、機械が関連する安全基準や規制に準拠しているかどうかも考慮してください。

操作とメンテナンスの容易さ

ユーザーフレンドリーなインターフェースと直感的なコントロールは、業務の効率と生産性に大きな違いをもたらします。操作とメンテナンスが簡単で、スタッフのトレーニングが最小限で済む袋詰め機を選択してください。また、スペアパーツの入手可能性とサービス サポートへのアクセスのしやすさも考慮してください。

予算の制約

最後に、袋詰め機を選択する際には予算を考慮してください。高品質の機械に投資することは不可欠ですが、予算の制約に合ったソリューションを見つけることも重要です。価格を比較し、エネルギー消費やメンテナンス費用などの長期的な所有コストを考慮してください。

結論

袋詰め機 包装プロセスの合理化を目指す企業にとって、機械は不可欠です。これらの機械のさまざまなタイプ、機能、用途を理解することで、企業は包装業務を強化し、製品のプレゼンテーションと配送の効率を向上させることができます。

キャンディー包装機のさまざまなタイプを理解したら、ビジネスに適した機械を選択することが重要です。

では、あなたのビジネスに最適なキャンディ包装機の種類は何でしょうか? その答えは、包装しようとしている製品と、必要な自動化のレベルによって異なります。

どのマシンが貴社に適しているかわからない場合は、今すぐ当社の専門家にお問い合わせください。

LTC Pack では、お客様のニーズに最適な機械を見つけるお手伝いをいたします。当社には幅広い機械の品揃えがあり、お客様のビジネスに最適な包装機械の選択に関するあらゆる質問にお答えできる知識豊富なスタッフがいます。