L'emballage est un terme général désignant le processus de chargement, d'emballage et de conditionnement quantitatif des produits. Il protège les produits et facilite leur transport, leur stockage et leur vente. L'emballage alimentaire doit être à la fois pratique et décoratif pour embellir et promouvoir les produits et attirer les consommateurs.

Type d'équipement d'emballage

Il existe de nombreux types d'emballages : selon les objectifs de vente des différents produits, on distingue : emballages industriels, emballages de marchandises et emballages militaires ; selon les fonctions, on distingue : emballages intérieurs (y compris l'emballage direct et l'emballage intermédiaire) et emballages extérieurs ; selon la nature du produit, on distingue : emballages en blocs, emballages de granulés, emballages de poudre, emballages de liquides, emballages de sauces, etc. ; selon les exigences spécifiques du produit, on distingue : emballages alimentaires, emballages étanches, emballages fragiles et emballages pour marchandises dangereuses. Les matériaux d'emballage doivent être non toxiques et conformes aux exigences nationales d'inspection sanitaire. Un accès facile doit également être exigé, et l'emballage doit permettre de résoudre le problème de l'incompatibilité entre étanchéité et accès facile.

Emballage intérieur Il s'agit de la forme d'emballage la plus élémentaire, comprenant l'emballage direct et l'emballage intermédiaire. L'emballage direct est un emballage où l'objet emballé et le matériau sont en contact direct. Par exemple, les emballages en papier pour bonbons, les emballages pour bouteilles de boissons, les emballages pour sachets de lessive, les emballages pour tubes de dentifrice, etc. L'emballage intermédiaire consiste à conditionner les produits directement emballés selon une quantité ou un modèle précis, par exemple en bouteilles ou en sacs, puis en cartons, ou encore en emballages combinés pour les cosmétiques.

Emballage extérieur Il s'agit de collecter un certain nombre de produits emballés en interne et de les reconditionner pour faciliter le transport et le stockage. L'emballage extérieur est généralement placé dans des boîtes en carton ou en bois, cerclées de sangles plates en plastique ou en fer. Les articles résistants à l'humidité doivent être doublés d'un film plastique et les articles résistants aux chocs, calés avec de la mousse plastique. Les spécifications, dimensions et marquages de l'emballage extérieur doivent être conformes aux normes nationales en vigueur.

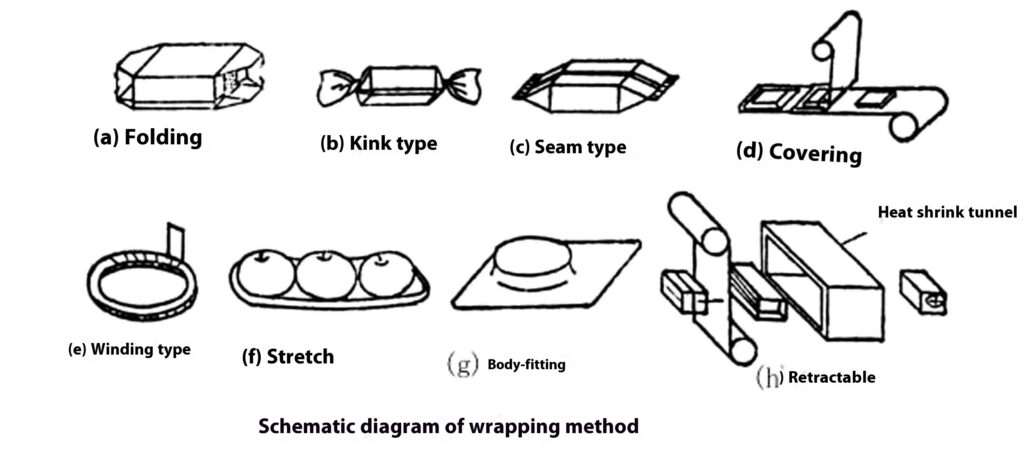

Les principales méthodes d'emballage des aliments Les options incluent l'embouteillage, la mise en conserve, la mise en boîte, l'ensachage, le conditionnement, le liage, etc., selon la nature du produit, les exigences de stockage et d'utilisation, les habitudes de vente régionales et la psychologie du client. Un même produit peut être conditionné sous différents modes : cartonné, simple, en vrac ; grand, petit, familial ; ou encore embouteillage, mise en boîte, mise en conserve et en sachet. L'objectif est de répondre aux besoins des différents objets de vente et des différents profils de consommateurs.

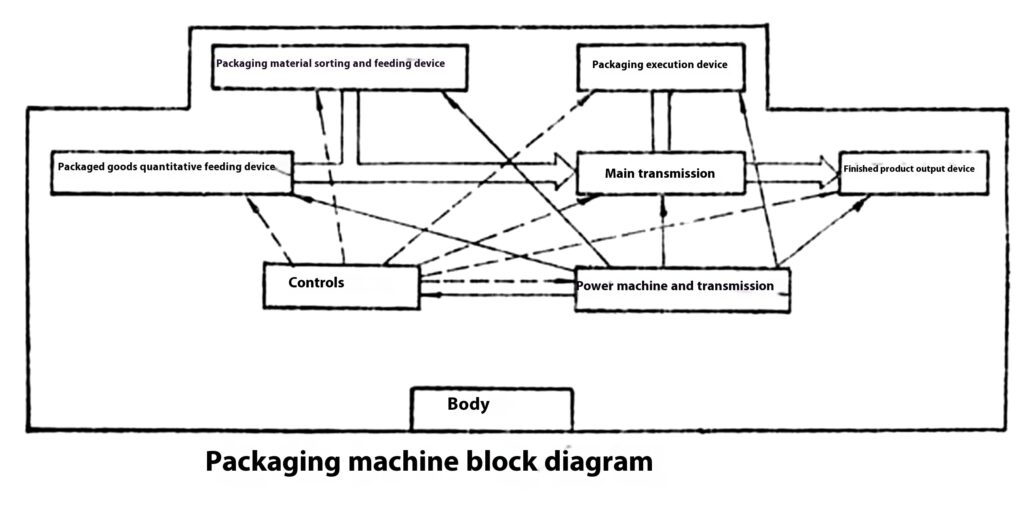

Composition des équipements d'emballage

La structure de la machine d'emballage est composée de trois parties : la partie puissance, la partie transmission et la partie exécution.

Afin de faciliter l'analyse et la compréhension du principe de fonctionnement et des caractéristiques structurelles de la machine d'emballage, nous décomposons en outre les trois principaux composants de la machine d'emballage en 8 aspects en fonction de leurs fonctions de travail, et les appelons les 8 éléments de la machine d'emballage.

Dispositif d'alimentation quantitative:Trier, mesurer, disposer et transporter les articles jusqu'à la station prédéterminée.

Dispositif de tri et d'alimentation:Coupez ou triez quantitativement et disposez les matériaux d'emballage ou les conteneurs et transportez-les jusqu'à la station prédéterminée.

Dispositif de transport principalDispositif permettant de transporter les articles et matériaux d'emballage d'un poste à l'autre, en séquence. Ce dispositif peut être omis pour les machines d'emballage à poste unique.

Dispositif d'exécution d'emballage:Un appareil qui effectue directement des opérations d'emballage telles que l'emballage, le remplissage, le scellage, l'étiquetage et le regroupement.

Dispositif de sortie du produit fini:Il s'agit d'un dispositif qui décharge le produit fini emballé du dispositif d'exécution d'emballage et l'envoie loin de la machine d'emballage.

Machine de puissance et dispositif de transmission: Une machine motrice est généralement un moteur électrique. Le dispositif de transmission comprend un réducteur, un mécanisme de transmission et de conversion de puissance et de mouvement, et peut prendre diverses formes, telles que mécanique, hydraulique, pneumatique, électromagnétique et optique.

Dispositif de contrôle:Il comprend le dispositif d'indication et de contrôle de la vitesse d'emballage, de la pression, de la température et du temps d'action, le dispositif de surveillance et de contrôle de la quantité et de la qualité de l'emballage et divers dispositifs de protection automatique de la machine.

Corps de la machineIl sert à soutenir et à fixer les pièces concernées afin de les maintenir en position de travail et de jouer un rôle protecteur pour la machine. Sa structure doit être facile à utiliser et à entretenir, et son aspect doit être aussi esthétique que possible.

Cette figure est un schéma fonctionnel de la machine d'emballage, illustrant la relation entre ses huit éléments. Les flèches doubles représentent le système de transport principal des matériaux d'emballage, les flèches continues représentent la transmission et les flèches pointillées la commande.

Conclusion

Les équipements d'emballage sont essentiels à la production industrielle légère. Ils sont largement utilisés dans les industries agroalimentaires, de produits de première nécessité, de cosmétiques, de médicaments, de textiles, de papeterie, de jouets, d'appareils électroménagers et de petits produits de quincaillerie, et interviennent en dernière étape du processus. Un emballage de mauvaise qualité a un impact important sur la qualité du produit et les bénéfices économiques.

Les équipements d'emballage modernes évoluent sans cesse. Ils évoluent rapidement en termes de vitesse, de qualité, de types d'emballage, de mécanisation et d'automatisation. La recherche et le développement de nouveaux procédés d'emballage, l'émergence de nouveaux matériaux de fabrication et d'emballage, ainsi que l'invention et l'utilisation de nouvelles technologies ont permis la conception et la fabrication de machines d'emballage modernes, performantes, rapides et de haute qualité.