When it comes to packaging food powders, selecting the right packaging machine is crucial for ensuring product quality, safety, and efficiency. With numerous options available in the market, it can be challenging to determine which machine is best suited for your specific needs. In this article, we will discuss the top 4 packaging machines for food powders, taking into account factors such as product characteristics, production capacity, and budget constraints.

Vacuum Filling Machine

The vacuum filling machine is an ideal choice for packaging food powders, particularly those that are prone to caking or clumping. This machine operates by creating a vacuum inside the packaging container, which helps to remove air and prevent oxidation. The powder is then introduced into the container, filling the space left by the removed air. This process ensures that the powder is packed tightly and evenly, minimizing the risk of clumping and improving overall product quality.

Vacuum filling machines are suitable for a wide range of food powders, including spices, seasonings, and baking mixes. They are also available in various sizes, making them suitable for both small-scale and large-scale production. However, it is essential to note that vacuum filling machines can be more expensive than other types of packaging machines, and they may require additional maintenance due to the complexity of their design.

Rotary Filling Machine

The rotary filling machine is another popular choice for packaging food powders. This machine operates by rotating a series of filling stations, where the powder is dispensed into the packaging containers. The filling process is precise and consistent, ensuring that each container receives the correct amount of product.

Rotary filling machines are suitable for a wide range of food powders, including sugar, flour, and coffee. They are also available in various sizes, making them suitable for both small-scale and large-scale production. One of the main advantages of rotary filling machines is their high production capacity, which makes them ideal for businesses with high demand. However, they can be more expensive than other types of packaging machines, and they may require more space due to their size.

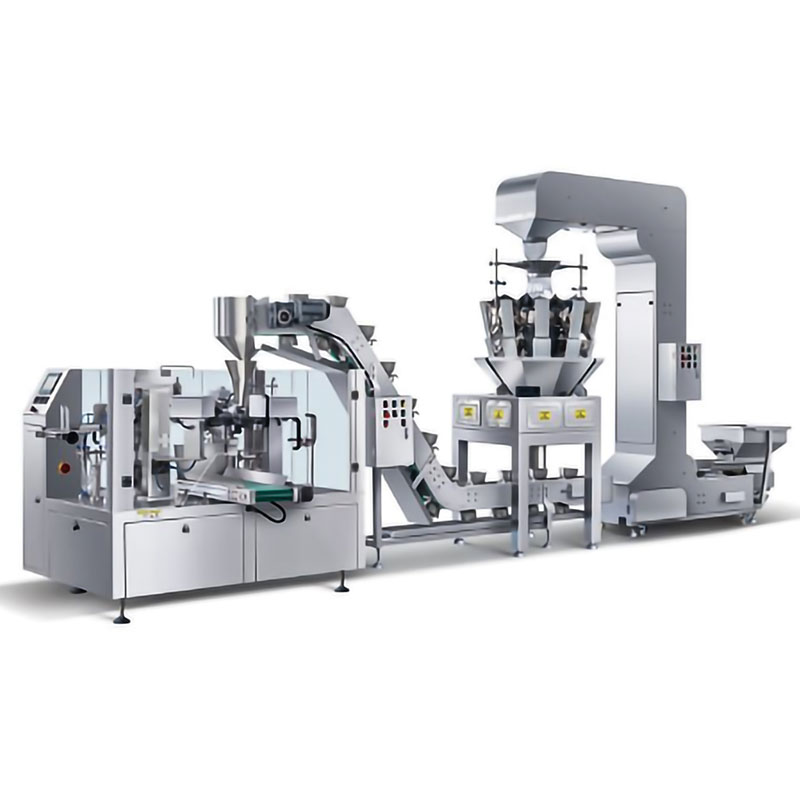

Weighing Filling Machine

The weighing filling machine is a versatile option for packaging food powders, as it allows for precise dosing of the product. This machine operates by weighing the desired amount of powder and dispensing it into the packaging container. The filling process is highly accurate, ensuring that each container receives the correct amount of product.

Weighing filling machines are suitable for a wide range of food powders, including pharmaceutical products and nutritional supplements. They are also available in various sizes, making them suitable for both small-scale and large-scale production. One of the main advantages of weighing filling machines is their ability to handle a wide range of product weights, which makes them highly flexible. However, they can be more expensive than other types of packaging machines, and they may require more maintenance due to the complexity of their design.

Auger Filling Machine

The auger filling machine is a simple and cost-effective option for packaging food powders. This machine operates by using a screw-like device to push the powder into the packaging container. The filling process is consistent and reliable, ensuring that each container receives the correct amount of product.

Auger filling machines are suitable for a wide range of food powders, including flour, sugar, and baking mixes. They are also available in various sizes, making them suitable for both small-scale and large-scale production. One of the main advantages of auger filling machines is their low cost, which makes them an attractive option for businesses with a limited budget. However, they may not be as accurate as other types of packaging machines, and they may require more manual intervention during the filling process.

Conclusion

Selecting the right packaging machine for food powders is crucial for ensuring product quality, safety, and efficiency. The vacuum filling machine is ideal for preventing clumping, the rotary filling machine is suitable for high production capacity, the weighing filling machine offers precise dosing, and the auger filling machine is a cost-effective option. By considering these factors, businesses can choose the best packaging machine for their specific needs and ensure the success of their food powder packaging operations.