Mit der rasanten Entwicklung der Heimtierbranche entscheiden sich immer mehr Menschen für Haustiere. Da Tierfutter ein unverzichtbarer Bestandteil des Tierlebens ist, ist es für Tierfutterhersteller besonders wichtig, geeignete Verpackungsmaterialien auszuwählen. Dieser Artikel befasst sich mit den Auswahlkriterien für Lebensmittelverpackungsmaterialien für Tierfutterhersteller.

Sicherheit von Lebensmittelverpackungsmaterialien

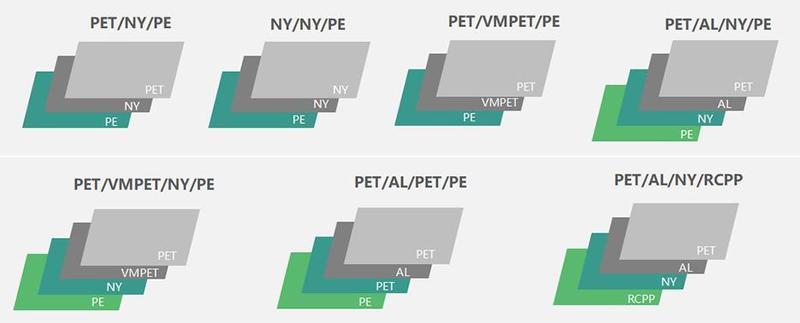

Die Sicherheit von Lebensmittelverpackungsmaterialien ist das wichtigste Auswahlkriterium. Für Tierfutterhersteller ist die Wahl sicherer und unbedenklicher Materialien Ausdruck ihrer Verantwortung gegenüber den Verbrauchern. Daher sollten bei der Auswahl von Lebensmittelverpackungsmaterialien lebensmittelechte Materialien wie PET, PP und andere ungiftige, geruchs- und schadstofffreie Materialien bevorzugt werden. Darüber hinaus muss sichergestellt werden, dass die Materialien den einschlägigen nationalen Lebensmittelsicherheitsstandards entsprechen und über die entsprechenden Zertifizierungen verfügen.

Frische von Lebensmittelverpackungsmaterialien

Die Erhaltung der Frische und des Geschmacks von Tiernahrung ist eines der wichtigsten Ziele der Lebensmittelverpackung. Daher sollte bei der Auswahl von Verpackungsmaterialien auf die Frischeeigenschaften geachtet werden. Generell eignen sich Materialien mit guter Sauerstoffisolation, Feuchtigkeitskontrolle und Feuchtigkeitsbeständigkeit besser als Verpackungsmaterialien für Tiernahrung. Beispielsweise verfügen Verpackungsbeutel aus Aluminiumfolie über gute Sauerstoffisolationseigenschaften, die Sauerstoff effektiv isolieren und die Haltbarkeit von Lebensmitteln verlängern können.

Korrosionsbeständigkeit von Lebensmittelverpackungsmaterialien

Als Lebensmittel muss Tiernahrung eine gute Korrosionsbeständigkeit in den Verpackungsmaterialien aufweisen. Bei der Auswahl der Verpackungsmaterialien sollten Sie leicht korrosive Materialien wie Eisenbleche vermeiden. Im Gegenteil, Materialien mit guter Korrosionsbeständigkeit, wie Kunststoff und Glas, eignen sich besser als Verpackungsmaterialien für Tiernahrung.

Recyclingfähigkeit von Lebensmittelverpackungsmaterialien

Umweltschutz und nachhaltige Entwicklung sind zu einem wichtigen Thema in der heutigen Gesellschaft geworden. Um die Umweltbelastung zu reduzieren, sollten Tierfutterhersteller recycelbaren Verpackungsmaterialien wie recycelbaren Kunststoffen wie PET und PP den Vorzug geben. Darüber hinaus können auch abbaubare Materialien wie biobasierte Kunststoffe zur Reduzierung der Umweltbelastung in Betracht gezogen werden.

Aussehensdesign von Lebensmittelverpackungsmaterialien

Das Design von Lebensmittelverpackungen ist für Tierfutterhersteller eine Möglichkeit, emotional mit den Verbrauchern zu kommunizieren. Durch ein exquisites Verpackungsdesign kann die Aufmerksamkeit der Verbraucher geweckt und das Markenimage gestärkt werden. Daher sollten wir bei der Auswahl von Lebensmittelverpackungen nicht nur auf die Funktionalität, sondern auch auf die Attraktivität des Designs achten, um die Wettbewerbsfähigkeit des Produkts zu steigern.

Kostenüberlegungen zu Lebensmittelverpackungsmaterialien

Obwohl Qualität und Funktion von Lebensmittelverpackungen von großer Bedeutung sind, spielen auch die Kosten eine wichtige Rolle für Unternehmen. Bei der Auswahl von Lebensmittelverpackungsmaterialien sollten die Kosten umfassend berücksichtigt und die kostengünstigsten Materialien ausgewählt werden. Tierfutterunternehmen können durch die Verwendung geeigneter Verpackungsmaterialien und eines sinnvollen Verpackungsdesigns Kosten senken und einen besseren wirtschaftlichen Nutzen erzielen.

Automatische Verpackungsmaschinen für Tiernahrung: Rationalisierung der Produktion und Sicherung der Qualität

Mit der steigenden Nachfrage nach Tiernahrung steigt auch der Bedarf an effizienten, zuverlässigen und sicheren Verpackungslösungen. Automatische Verpackungsmaschinen sind zu einem Eckpfeiler für Tierfutterhersteller geworden und bieten zahlreiche Vorteile in Bezug auf Effizienz, Konsistenz und Produktschutz. Diese Maschinen sind speziell auf die besonderen Anforderungen von Tierfutter ausgelegt und stellen sicher, dass das Endprodukt den Verbraucher in optimalem Zustand erreicht. Aus diesen Gründen ist die automatische Verpackung für die Tierfutterindustrie von entscheidender Bedeutung:

1. Maßgeschneidert für verschiedene Tierfutterformate

Tierfutter gibt es in einer Vielzahl von Formaten, von Trockenfutter und Nassfutter bis hin zu Leckerlis und Nahrungsergänzungsmitteln. Automatische Verpackungsmaschinen können an die unterschiedlichen Verpackungsanforderungen dieser vielfältigen Produkte angepasst werden. Ob kleine Tüten mit Hundeleckerlis oder große Tüten mit Katzenfutter – automatische Maschinen sind vielseitig genug, um einen schnellen Wechsel zwischen Verpackungsgrößen und -arten zu gewährleisten.

2. Optimierte Frische und Versiegelungsintegrität

Eines der Hauptanliegen bei der Verpackung von Tiernahrung ist die Aufrechterhaltung der Frische Und Sicherheit des Produkts. Automatische Verpackungsmaschinen tragen dazu bei, indem sie fortschrittliche Versiegelungstechnologie verwenden, um luftdichte Versiegelungen zu gewährleisten. Dies verhindert, dass Luft, Feuchtigkeit und Verunreinigungen die Produktqualität beeinträchtigen. Ob mit Vakuumieren, Stickstoffspülung, oder Heißsiegeln Mithilfe dieser Methoden können automatische Maschinen Tierfutter länger frisch halten, was für die Haltbarkeit und die Gesundheit des Haustiers von entscheidender Bedeutung ist.

3. Präzision und Konsistenz beim Portionieren

Für Tierfutterhersteller ist die Einhaltung präziser Portionsgrößen unerlässlich. Automatische Verpackungsmaschinen gewährleisten eine präzise Befüllung und minimieren so die Über- oder Unterfüllung der Beutel. Dieses Maß an Genauigkeit Und Konsistenz stellt sicher, dass jede Packung Tierfutter die genauen Gewichts- und Portionsspezifikationen erfüllt, was die Kundenzufriedenheit verbessert und Produktabfälle reduziert.

4. Effiziente Großverpackung

Neben Einzelverpackungen für den Einzelhandel müssen Tierfutterhersteller ihre Produkte häufig auch in Großmengen für den Großhandel oder größere Lager verpacken. Automatische Verpackungsmaschinen können große Mengen Tierfutter effizient verarbeiten und so den manuellen Arbeitsaufwand reduzieren. Durch die Automatisierung des Großverpackungsprozesses können Hersteller die Produktion beschleunigen, Fehler reduzieren und die Betriebseffizienz insgesamt verbessern.

5. Verbesserte Hygiene und Sicherheit

Angesichts des Kontaminationsrisikos hat Hygiene bei der Verpackung von Tierfutter höchste Priorität. Automatische Verpackungsmaschinen sind mit hygieneorientierten Merkmalen ausgestattet, wie z. B. leicht zu reinigenden Komponenten, geschlossenen Systemen zur Vermeidung von Staubansammlungen und bakterienhemmenden Materialien. Dadurch wird sichergestellt, dass die Verpackungsumgebung sauber bleibt und das Futter während des gesamten Prozesses unversehrt bleibt.

6. Nachhaltige Verpackungsoptionen

Angesichts des zunehmenden Umweltbewusstseins versuchen immer mehr Tierfutterhersteller, ihre Umweltbelastung zu reduzieren. Automatische Verpackungsmaschinen sind kompatibel mit umweltfreundliche Materialien, wie recycelbare Kunststoffe oder biologisch abbaubare Beutel. Darüber hinaus verfügen diese Maschinen oft über Designelemente, die durch präzise Verpackungsmaße den Materialabfall reduzieren und so zu nachhaltigeren Produktionspraktiken beitragen.

7. Verbesserte Produktionsgeschwindigkeit und Kosteneffizienz

Durch die Automatisierung des Verpackungsprozesses können Tierfutterhersteller ihre Produktionsgeschwindigkeit deutlich steigern. Automatische Maschinen können im Vergleich zur manuellen Verpackung Tausende von Einheiten pro Stunde verpacken, was Zeit und Arbeitskosten spart. Diese Hochgeschwindigkeitsverpackung führt zudem zu weniger Fehlern, reduziert Produktverluste und steigert die Gesamtrentabilität.

8. Skalierbarkeit und Flexibilität

Mit dem Wachstum und der Diversifizierung von Tierfuttermarken können sich auch deren Verpackungsanforderungen ändern. Automatische Verpackungsmaschinen bieten Skalierbarkeit und ermöglichen es Herstellern, sich ohne größere Betriebsunterbrechungen an steigende Produktionsanforderungen anzupassen oder neue Verpackungsformate einzuführen. Ob Sie in neue Tierfutterkategorien expandieren oder Verpackungsgrößen anpassen – diese Maschinen bieten die nötige Flexibilität für Wachstum und Anpassung in einem dynamischen Markt.

Abschluss

Die Wahl geeigneter Verpackungsmaterialien ist für Tierfutterhersteller entscheidend. Um die Lebensmittelsicherheit zu gewährleisten, sollten Faktoren wie Frische, Korrosionsbeständigkeit, Recyclingfähigkeit, Design und Materialkosten berücksichtigt werden. Nur durch die Wahl standardisierter und geeigneter Verpackungsmaterialien können Tierfutterhersteller die Produktqualität effektiv verbessern, die Bedürfnisse der Verbraucher erfüllen und sich im Wettbewerb behaupten.

LTC-Paket ist ein führender Anbieter von Anlagen- und Servicelösungen für die Verpackung von Getränken, Lebensmitteln, Haushalts- und Körperpflegeprodukten in Beuteln, Dosen, Glas und anderen Materialien. Mit über 40.000 installierten Maschinen in mehr als 190 Ländern verfügen wir über fast 20 Jahre bewährte Erfahrung und legen dabei einen starken Fokus auf die Fabrik von morgen.

Eine Lösung für jeden Bedarf. Vom Verpacken und Blasen über das Abfüllen, Etikettieren und Verpacken bis hin zum Palettieren haben wir Lösungen für jeden Bedarf.