Are you finding it challenging to meet the rising demand for perfectly portioned sugar sachets? This article explores the world of sugar sachet packing machines, highlighting their benefits, types, and cost considerations. Discover how these machines can streamline your packaging process and address sustainability concerns, ultimately elevating your business to new levels of efficiency and profitability.

What is a Sugar Sachet Packing Machine and Why is it Essential?

A sugar sachet packing machine is an automated device designed to fill and seal individual packets, or sachets, with a specific amount of sugar. Imagine the little sugar packets you receive at coffee shops or restaurants—that’s the magic of these machines. By automating the packaging process, these machines eliminate the need for manual filling, which can be time-consuming and prone to errors.

Benefits:

- Consistency: Ensures each sachet contains the exact amount of sugar.

- Hygiene: Minimizes human contact, maintaining sanitary standards.

- Efficiency: Increases production speed, meeting high demand effortlessly.

Personal Experience:

In my early days in the packaging industry, I worked with a small cafe owner who manually filled each sugar sachet. As their business grew, this method became a bottleneck. Investing in a semi-automatic sugar sachet machine transformed their operations—output soared, and consistency improved, leading to higher customer satisfaction.

What Determines the Sugar Sachet Packing Machine Price?

Several factors influence the sugar sachet packing machine price:

- Automation Level: Fully automatic machines are pricier but offer greater efficiency compared to semi-automatic ones.

- Production Capacity: Machines designed for high-volume output generally cost more.

- Material Quality: Durable materials and advanced components increase the price.

- Brand Reputation: Established brands may charge a premium for reliability and support.

- Additional Features: Touchscreen interfaces, multi-packing capabilities, and advanced sealing technologies can add to the cost.

Table: Factors Affecting Machine Price

| Factor | Impact on Price |

|---|---|

| Automation Level | Higher automation, higher cost |

| Production Capacity | Higher capacity, higher cost |

| Material Quality | Durable materials, higher cost |

| Brand Reputation | Trusted brands, premium price |

| Additional Features | More features, higher cost |

Insight:

I once consulted for a company that chose a cheaper machine to save on initial costs. However, frequent breakdowns and costly repairs ended up being more expensive in the long run. It’s crucial to consider the total cost of ownership, including maintenance and support, not just the upfront price.

Is a Sachet Packing Machine Price Worth the Investment?

Deciding if the sachet packing machine price is worth it involves assessing your business needs and potential return on investment (ROI).

Considerations:

- Demand: Are you struggling to keep up with orders manually?

- Labor Costs: Automation can significantly reduce labor expenses.

- Consistency: Improved packaging quality enhances your brand image.

- Scalability: Ability to scale production quickly to meet growing demand.

Example:

Businesses that invested in sachet packing machines often see a quick ROI through reduced labor costs, increased output, and improved product quality. It’s not just about saving money; it’s about enhancing efficiency and opening new growth opportunities.

Unpacking the Different Types of Sugar Sachet Machine

There are primarily two types of sugar sachet machines:

- Vertical Form-Fill-Seal (VFFS) Machines:

- Pros: Versatile, compact footprint, suitable for various sachet sizes.

- Ideal For: High-volume production with flexibility.

- Horizontal Form-Fill-Seal (HFFS) Machines:

- Pros: Higher speed, specific sachet shapes.

- Ideal For: Large-scale operations requiring fast packaging.

Choosing the Right Type: Assess your production volume, sachet size, and available space to determine which machine suits your needs best.

Personal Insight:

A client initially opted for a high-speed HFFS machine but later switched to a more compact VFFS machine after realizing their space was limited. This decision optimized their production without compromising efficiency.

Can I Use the Same Machine for Sugar Packing Machine 1kg and Sachets?

Using the same machine for both 1kg sugar packing and small sachets is generally not feasible. Here’s why:

- Different Mechanisms: Machines for larger bags use different filling and sealing mechanisms compared to sachet machines.

- Precision: Sachet machines require higher precision for accurate filling and consistent sealing.

- Material Handling: Sachet machines are designed for delicate films, while 1kg machines handle more robust materials.

Analogy:

It’s like trying to use a hammer to drive a tiny screw—you need the right tool for the job.

Recommendation:

Invest in dedicated machines for each packaging format to ensure efficiency and accuracy.

What Are the Best Options for Sugar Packaging Bags?

Choosing the right sugar packaging bags is crucial for product protection, shelf life, and brand presentation.

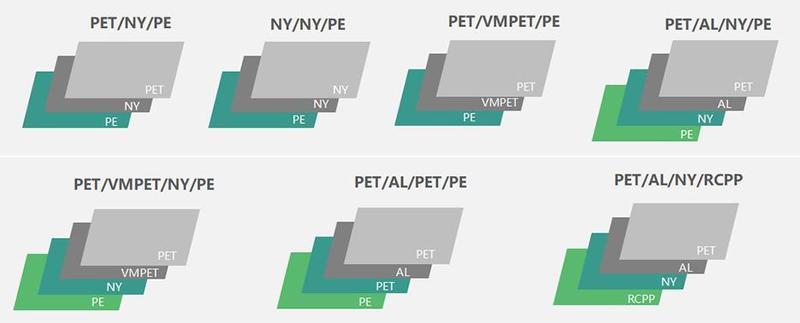

Common Materials:

- Polyethylene (PE): Cost-effective with a good moisture barrier.

- Polypropylene (PP): Higher heat resistance, suitable for hot-fill applications.

- Laminates: Combine materials like paper, PE, and aluminum foil for excellent barrier properties.

Considerations:

- Moisture Barrier: Keeps sugar fresh and free-flowing.

- Print Quality: High-quality materials allow for better branding and graphics.

- Environmental Impact: Recyclable or compostable options are increasingly popular.

Personal Insight:

Businesses that choose eco-friendly packaging not only contribute to environmental conservation but also appeal to environmentally conscious consumers, enhancing their brand reputation.

How Does Automation Enhance Efficiency in Sugar Sachet Packing?

Automation through a sugar sachet packing machine revolutionizes efficiency in several ways:

- Increased Production Speed: Machines can fill and seal hundreds or thousands of sachets per hour, far surpassing manual methods.

- Consistent Portion Control: Ensures each sachet has the exact amount of sugar, maintaining product quality.

- Reduced Labor Costs: Minimizes the need for manual labor, lowering operational expenses.

- Minimized Human Error: Automation ensures accuracy and reduces the risk of mistakes.

Example:

Companies that implemented automated packing lines experienced a significant boost in production capacity, allowing them to meet higher demand without compromising quality.

What Role Does Sustainability Play in Modern Sugar Sachet Packaging?

Sustainability is a key focus in today’s packaging industry. Here’s how it impacts sugar sachet packaging:

- Eco-Friendly Materials: Using recyclable or compostable films reduces environmental impact.

- Energy-Efficient Machines: Modern packing machines consume less energy, lowering operational costs and carbon footprint.

- Waste Reduction: Precision in filling minimizes product waste and packaging material usage.

Benefits:

- Environmental Conservation: Reduces reliance on traditional plastics.

- Enhanced Brand Image: Consumers prefer brands that prioritize sustainability.

- Regulatory Compliance: Meets increasing environmental regulations and standards.

Personal Insight:

Adopting sustainable practices not only benefits the planet but also attracts a loyal customer base that values eco-friendly initiatives.

How to Choose the Right Sugar Sachet Packing Machine for Your Business?

Selecting the ideal sugar sachet packing machine involves evaluating several factors:

- Production Volume: Determine how many sachets you need to produce daily or weekly.

- Sachet Size and Shape: Ensure the machine can handle your specific packaging requirements.

- Material Compatibility: Choose a machine compatible with your chosen packaging materials.

- Automation Level: Decide between fully automatic or semi-automatic machines based on your operational needs.

- Space Availability: Consider the machine’s footprint to fit your production area.

- Budget: Balance the initial cost with long-term benefits and maintenance expenses.

- Manufacturer Reputation: Opt for reliable brands that offer good support and warranty.

Steps to Choose:

- Assess Needs: Define your production and packaging requirements.

- Research Options: Compare different machine types and features.

- Request Quotes: Obtain detailed quotes from multiple suppliers.

- Evaluate Support: Consider the level of customer support and maintenance services offered.

- Test Machines: If possible, see the machines in action or request demonstrations.

What’s the Future of Sugar Sachet Packing Technology?

The future of sugar sachet packing technology is promising, driven by advancements in automation, materials science, and sustainability.

Emerging Trends:

- Smart Packaging: Integration of IoT for real-time monitoring and data analytics.

- AI and Machine Learning: Enhancing machine efficiency and predictive maintenance.

- Biodegradable Materials: Increased use of eco-friendly packaging films.

- Customization: Flexible machines that can adapt to various packaging formats and sizes.

- Energy Efficiency: Continued focus on reducing energy consumption in packaging operations.

Prediction:

Technological innovations will lead to smarter, more efficient, and environmentally friendly packing solutions, helping businesses stay competitive and sustainable.