تخيّل آلة خارقة قادرة على تحويل البلاستيك المسطح إلى أكياس، وملؤها بسرعة بوجبات خفيفة لذيذة أو ألعاب رائعة، وإغلاقها بإحكام - كل ذلك في لمح البصر! هذا بالضبط ما يفعله... آلة تعبئة الأكياس العمودية، والمعروفة أيضًا باسم آلة التعبئة والتغليف العموديةهذه الآلات الرائعة تضمن وصول منتجاتك المفضلة إليك بأمان وكفاءة. انضم إلينا في رحلة ممتعة لاكتشاف كيفية عمل هذه الآلات وأهميتها، كل ذلك دون الخوض في تفاصيل تقنية معقدة. استعد لتجربة تعبئة رائعة!

ما هي الآلة العمودية بالضبط وما الذي يجعلها مميزة جدًا؟

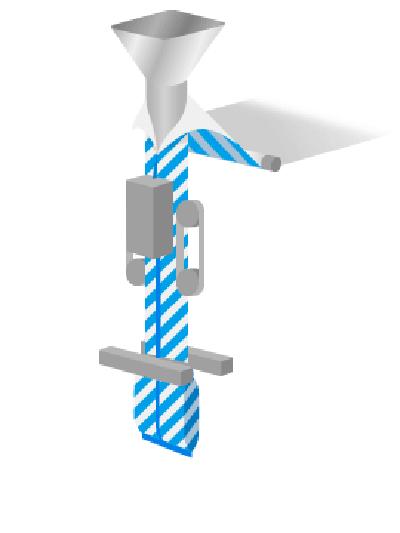

تخيّل روبوتًا طويل القامة واقفًا منتصبًا - هذا يُشبه شكل آلة التعبئة العمودية! على عكس الآلات الجانبية، آلات التعبئة والختم العمودية (أو آلات VFFS باختصار، خذ لفافة بلاستيكية مسطحة، وحولها، بطريقة سحرية، إلى كيس، املأه بالمنتجات، وأغلقه بإحكام. تتميز هذه الآلات بسرعتها الفائقة وصغر حجمها، مما يجعلها خيارًا مفضلًا في المصانع التي تحتاج إلى تعبئة كميات كبيرة بسرعة، سواءً كانت رقائق البطاطس أو طعام الحيوانات الأليفة.

كم تكلفة الماكينة العمودية فعليًا؟

ربما تفكر، "تبدو هذه الآلات مذهلة، ولكن ما هو سعر الآلة العموديةيشبه الأمر إلى حد ما السؤال عن سعر السيارة، إذ يعتمد على الطراز وميزاته. ختم الشكل العمودي قد يتراوح سعر الماكينة بين 20,000 و50,000 دولار أمريكي، بينما قد يتراوح سعر الطُرز الأكثر تطورًا المزودة بسحّابات خاصة أو أشكال فريدة للحقائب بين 80,000 و200,000 دولار أمريكي فأكثر. وتؤثر عوامل مثل سرعة الماكينة، وسعة الحقيبة، والتجهيزات الإضافية، على السعر النهائي.

مقارنة بين آلات التعبئة العمودية الأساسية والمتقدمة

| ميزة | النموذج الأساسي | النموذج المتقدم |

|---|---|---|

| السرعة (أكياس/دقيقة) | 30-50 | 80-120 |

| نطاق حجم الحقيبة | محدود | مجموعة واسعة |

| نوع الختم | ختم الحرارة | نبضة/فوق صوتية |

| مستوى الأتمتة | التعديلات اليدوية | التعديلات التلقائية |

| نطاق السعر | $20,000 – $50,000 | $80,000 – $200,000+ |

ما هو السر وراء القدرات المذهلة لآلة تعبئة وختم النموذج العمودي؟

تخيل قطعة ضخمة من ورق التغليف، وهي عبارة عن لفافة من الفيلم البلاستيكي. آلة تعبئة وختم القالب العمودي يُمرر هذا الغشاء عبر أنبوب خاص، ويُطوى ويُغلق من الخلف ليأخذ شكل الأنبوب. يُغلق الجزء السفلي من الأنبوب ليشكل قاعدة الكيس، وتُوضع فيه منتجات مثل الحلوى أو المكسرات، ثم يُغلق الجزء العلوي ويُقطع. ها هو ذا! لديك منتج مُغلّف بإتقان، جاهز للاستخدام. يشبه الأمر مصنعًا صغيرًا متكاملًا. يُمكنك مشاهدة هذه العملية عمليًا في العديد من فيديوهات جولات المصانع على الإنترنت.

لماذا تعتبر آلة التعبئة والتغليف العمودية شائعة جدًا في عالم التعبئة والتغليف؟

فكّر في جميع المنتجات المختلفة التي تحتاج إلى تغليف - الوجبات الخفيفة، والمساحيق، والسوائل، وغيرها! آلة تعبئة وختم عمودية تتميز هذه الآلات بتعدد استخداماتها، حيث تتعامل مع مواد وأحجام أكياس متنوعة. بفضل عمليات التشكيل والتعبئة والغلق في عملية واحدة متواصلة، توفر هذه الآلات للشركات الوقت والمال. كما تضمن سرعتها وصول المنتجات إلى رفوف المتاجر بسرعة، مما يجعلها أساسية في صناعة التعبئة والتغليف.

من هم العقول المدبرة وراء مصنعي آلات VFFS؟

مثلما توجد ماركات مختلفة للسيارات، تتخصص العديد من الشركات في تصنيعها آلات VFFS. هؤلاء مصنعي آلات تعبئة وختم القوالب يصممون ويصنعون هذه الآلات المعقدة، حيث يركز بعضها على تغليف المواد الغذائية، بينما يركز البعض الآخر على منتجات مثل الأجهزة أو مستلزمات التنظيف. يبتكر هؤلاء المصنعون باستمرار، ويطورون آلاتهم لتصبح أسرع وأكثر كفاءة وتنوعًا.

LTC Pack هي شركة رائدة في توفير حلول المعدات والخدمات لتعبئة المشروبات والأغذية ومنتجات العناية المنزلية والشخصية في الأكياس والعلب والزجاج وغيرها من المواد. مع أكثر من 40000 آلة مثبتة في أكثر من 190 دولة، لدينا ما يقرب من 20 عامًا من الخبرة المثبتة، مع التركيز القوي على مصنع الغد مع الأنظمة المتقدمة وهندسة الخطوط والابتكار. إن موظفينا البالغ عددهم 500 موظف حول العالم متحمسون لتقديم حلول تلبي احتياجات العملاء وتعزز أداء خطوطهم ومنتجاتهم وأعمالهم. يتطلب تقديم هذا المستوى من الأداء أن نبقى مرنين. نحن نضمن باستمرار أننا نفهم التحديات المتغيرة لعملائنا ونلتزم بتحقيق أهداف الأداء والاستدامة الفريدة الخاصة بهم. نقوم بذلك من خلال الحوار وفهم احتياجات أسواقهم وإنتاجهم وسلاسل القيمة الخاصة بهم. وفي المقابل، نطبق معرفتنا التقنية الراسخة وتحليلات البيانات الذكية لضمان وصول الإنتاجية مدى الحياة إلى أقصى إمكاناتها. نحن نسميها الأداء من خلال الفهم.

كيف تختار سعر الماكينة العمودية المناسب لاحتياجاتك؟

اختيار آلة التعبئة العمودية المناسبة أشبه باختيار الحذاء المثالي - فأنت بحاجة إلى المقاس المناسب! ابدأ بالتفكير فيما ستعبأه: هل هو خفيف ورقيق مثل رقائق البطاطس أم ثقيل مثل طعام الكلاب؟ كم عدد الأكياس التي تحتاج إلى إنتاجها يوميًا؟ ما هو الحجم المناسب للأكياس؟ ستساعدك هذه العوامل في تحديد نوع الآلة التي تحتاجها والوزن المناسب. سعر الآلة العمودية من الحكمة أيضًا استشارة الخبراء الذين يمكنهم إرشادك إلى الخيار الأفضل لاحتياجاتك المحددة.

ما هي الميزات الرائعة التي يمكنك العثور عليها في آلة التعبئة والتغليف العمودية الحديثة؟

آلات التعبئة العمودية اليوم مزودة بتقنيات متطورة! بعضها مزود بأجهزة استشعار ذكية تضمن ملء كل كيس بدقة، بينما يمكن للبعض الآخر... تواريخ الطباعة ومعلومات مهمة مباشرة على الكيس. حتى أن هناك آلات مزودة بميزات خاصة للحفاظ على الطعام طازجًا لفترة أطول. تخيل هذه الميزات، مثل نظام الملاحة في السيارة أو كاميرا احتياطية، تجعل الآلة أكثر فائدة وكفاءة. على سبيل المثال، يمكن لبعض الآلات المتطورة ضبط الإعدادات تلقائيًا لأنواع مختلفة من المنتجات، مما يوفر لك وقتًا ثمينًا.

ما الذي يجعل آلة التعبئة والتغليف العمودية مختلفة عن الأخرى؟

كما هو الحال مع السيارات بمختلف طرزها، تختلف آلات التعبئة العمودية في جوانب عديدة. بعضها مصمم للسرعة، حيث ينتج مئات الأكياس بسرعة، بينما يُولي البعض الآخر المرونة، فيتعامل مع أحجام الأكياس والمواد المختلفة بسهولة. بعض الآلات سهلة الاستخدام مع أدوات تحكم بسيطة، بينما يوفر بعضها الآخر إعدادات أكثر تعقيدًا لاحتياجات التعبئة والتغليف المحددة. يكمن السر في العثور على آلة تُلبي احتياجاتك الخاصة، تمامًا كما هو الحال مع الاختيار بين شاحنة لنقل المعدات الثقيلة وسيارة صغيرة للقيادة داخل المدينة.

| نموذج | LTC420V | LTC520V | LTC620V | LTC720V |

| سعة | 40 كيسًا/دقيقة | 35 كيسًا/دقيقة | 50 كيس/دقيقة | 45 كيسًا/دقيقة |

| دقة | ≤±1.5% | ≤±1.5% | ≤±1.5% | ≤±1.5% |

| حجم الحقيبة | (عرض) 90-200 مم (طول) 60-300 مم | (عرض) 110-260 مم (طول) 80-350 مم | (عرض) 100-300 مم (طول) 20-400 مم | (عرض) 140-350 مم (طول) 20-450 مم |

| عرض الفيلم | 420 ملم | 520 ملم | 620 ملم | 730 ملم |

| نوع الحقيبة | يتم التعبئة باستخدام الفيلم والختم العلوي والختم السفلي والختم الخلفي بواسطة آلة تصنيع الأكياس الأوتوماتيكية. | |||

| سمك الفيلم | 0.06-0.08 مم، الأفضل هو 0.07-0.08 مم | |||

| مواد التغليف | المواد المركبة الحرارية، مثل BOPP/CPP، PET/AL/PE وما إلى ذلك | |||

| استهلاك الهواء | 0.8 ميجا باسكال 0.5 متر مكعب/دقيقة | 0.8 ميجا باسكال 0.3 متر مكعب/دقيقة | 0.8 ميجا باسكال 0.6 متر مكعب/دقيقة | 0.8 ميجا باسكال 0.8 متر مكعب/دقيقة |

| مسحوق إجمالي | 3.2 كيلو واط | 2.545 كيلو وات | 6.545 كيلوواط | 6.545 كيلوواط |

| الجهد االكهربى | أربعة أسلاك ثلاثية الطور، 380 فولت 50 هرتز | |||

| ضاغط الهواء | لا يقل عن 1.2 متر مكعب (يجب على المستخدم توفير ضاغط الهواء) | |||

| الارتفاع الإجمالي | 2.544 متر | 3.761 مليون | 3.76 متر | 3.955 متر |

التطلع إلى المستقبل: ما هو التالي بالنسبة لآلات التعبئة والتغليف العمودية؟

إن عالم التعبئة والتغليف يتطور دائمًا، آلات التعبئة والختم العمودية تزداد ذكاءً! يعمل المهندسون على جعل هذه الآلات أسرع وأكثر كفاءةً وقابليةً للتكيف. تخيّل آلاتٍ يمكنها التبديل تلقائيًا بين تغليف المنتجات المختلفة، أو حتى إصلاح المشاكل البسيطة تلقائيًا! من المرجح أيضًا أن نرى المزيد من الميزات الصديقة للبيئة، مثل إمكانية استخدام مواد تغليف قابلة للتحلل الحيوي. يحمل المستقبل تطوراتٍ مثيرة لهذه الآلات الرائعة.

اكتشف المزيد عن آلات التعبئة العمودية

- حلول التغليف العمودي عالية السرعة:عزز كفاءة خط الإنتاج الخاص بك.

- معدات التعبئة والتغليف VFFS:إحداث ثورة في صناعة الوجبات الخفيفة.

- آلات التعبئة والتغليف متعددة الاستخدامات:مناسبة لأنواع مختلفة من المنتجات.

- أنظمة التعبئة التلقائية:تبسيط عملياتك.

- خطوط التعبئة والتغليف المتكاملة:تتميز بأكياسنا العمودية عالية الجودة.