What Exactly is a Vertical Bagging Machine and How Does it Work?

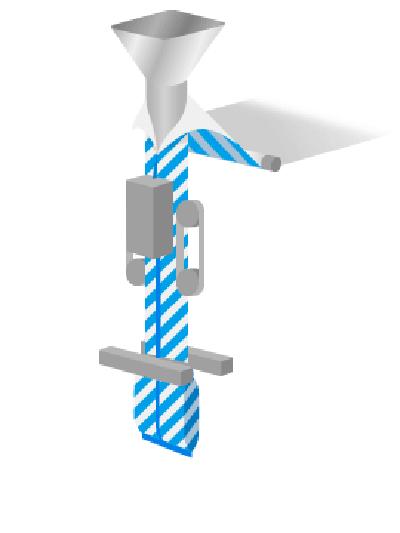

A vertical bagging machine, also known as a Vertical Form Fill Seal (VFFS) machine, takes a single roll of flat packaging film and turns it into a sealed, filled bag—in one swift, automated process. Here’s what that means for you:

- Film Formation: The machine draws the film vertically down through a shaping collar to form a tube.

- Sealing the Bag: A sealing jaw fuses the bottom of the tube to create the first seal.

- Filling the Product: Your product—whether it’s coffee beans, candy, or any number of items—drops into the newly formed bag.

- Final Seal & Cut: The top of the bag is sealed and then cut, creating a ready-to-ship package.

Thanks to its vertical orientation and continuous motion, a VFFS machine can produce a high volume of bags with consistent seal integrity—meaning fewer rejects and rework for you.

Why are Vertical Form Fill Seal Machines (VFFS) So Popular?

If you’re wondering why VFFS machines are making waves in nearly every industry, consider the following:

- Efficiency: They streamline multiple steps—forming, filling, and sealing—into a single, automated sequence. This drastically cuts labor costs and boosts output.

- Versatility: Whether you’re packaging powders, liquids, or solids, VFFS machines can handle various product types and bag sizes with minimal changeover time.

- Precision & Quality: Accurate filling and airtight sealing help reduce waste, maintain freshness, and ensure a consistent final product.

For companies looking to optimize speed, cost, and quality all at once, VFFS machines often top the list of must-have equipment.

What Factors Influence the Price of a Vertical Machine?

Vertical bagging machines can span a wide price range, so you’ll want to know where your money is going. Key factors include:

- Automation Level: More advanced features (like servo-driven motion or integrated checkweighers) typically push up the price.

- Construction & Material Compatibility: Machines built to handle corrosive or specialized materials require sturdier components.

- Speed & Capacity: High-throughput machines for large-scale operations often come with a higher price tag.

- Brand & Support: Well-established manufacturers may cost more but often provide better reliability, warranties, and service options.

- Customization: Tailored solutions to match unique product specs or packaging designs can raise the initial investment.

Striking the right balance between initial costs, long-term reliability, and production demands is crucial. Be sure to look beyond price alone when evaluating any machine.

How Can a Vertical Bagger Machine Improve Production Efficiency?

From a user’s standpoint, production efficiency can make or break profitability. Here’s how a vertical bagger machine can help:

- Reduced Manual Labor: Automation takes over repetitive tasks like forming, filling, and sealing, freeing up your workforce for other critical activities.

- Faster Throughput: Continuous motion bagging means you can produce more units in less time, meeting higher-volume orders without compromising quality.

- Minimized Waste: Precise filling systems ensure each bag has the right quantity, reducing product overfill or spillage.

- Quick Changeovers: Many VFFS machines offer easy-to-adjust settings, so transitioning between different products or bag sizes is a snap.

The result? Lower operational costs, fewer bottlenecks, and a more consistent product output that pleases both your team and your customers.

What Are the Different Types of Vertical Form Fill Seal Machines Available?

Your product type, production level, and desired bag style will shape the type of VFFS machine you need. Common categories include:

- Intermittent Motion VFFS

- Ideal For: Small to medium production runs

- Pros: Budget-friendly, simpler motion control

- Cons: Slower output compared to continuous machines

- Continuous Motion VFFS

- Ideal For: High-volume operations

- Pros: Faster packaging speeds, reduced downtime

- Cons: Typically more expensive upfront

- Auger Fill VFFS

- Ideal For: Powders and fine granules (e.g., flour, spices)

- Pros: Accurate dosing for lightweight, powdery products

- Cup Fill VFFS

- Ideal For: Granular solids like nuts, candies, or seeds

- Pros: Quick and easy volumetric filling

- Liquid Fill VFFS

- Ideal For: Beverages, sauces, other liquid or viscous products

- Pros: Specialized pumps and seals to prevent leaks

Matching the machine type to your product ensures you’ll get the best performance and packaging consistency.

How to Choose the Right VFFS Machine for Your Specific Needs

Selecting the right machine often starts with these questions:

- What’s Your Product?

- Powder, liquid, or solid? The right filler and sealing mechanism matter.

- Which Bag Types and Sizes Do You Need?

- Pillow pack, gusseted, quad seal? Make sure the machine handles your desired format.

- What Production Volumes Are You Aiming For?

- Higher volumes typically need continuous motion systems.

- What’s Your Budget and Space Availability?

- Factor in initial costs, maintenance, spare parts, and how much floor space you have.

- Do You Require Special Features?

- Advanced sealing? Gas flushing? Custom printing on the packaging film? Each adds complexity and cost.

By mapping these considerations to specific features, you’ll quickly narrow down the best-fit VFFS machines for your operation.

Who are the Leading Vertical Form Fill Seal Machine Manufacturers?

When it comes to reliability and innovation, certain names stand out:

- Syntegon (formerly Bosch Packaging Technology): Renowned for cutting-edge automation and comprehensive service support.

- Hayssen: Known for versatile, high-quality machines and extensive industry experience.

- Viking Masek: Offers both standard and highly customizable machines, catering to diverse customer needs.

- ROVEMA & Ishida: Innovators in the packaging space, consistently praised for robust machinery and advanced design.

- Lintyco Pack : Known by their high speed and excelent seal level.

A well-known brand often brings solid warranties and easier access to spare parts—but always weigh these advantages against your specific packaging requirements and budget.

Form Fill Seal Machine Manufacturers: What to Consider When Choosing a Supplier

Choosing the right supplier can be just as critical as selecting the machine itself. Before you sign on the dotted line, ask:

- How Reputable Is the Supplier?

- Check customer reviews, testimonials, and how long they’ve been in business.

- Do They Offer Strong Technical Support?

- Installation, training, and after-sales service are key to minimizing downtime.

- Are Spare Parts Readily Available?

- Quick part replacements can save you from costly production halts.

- Can They Customize Solutions?

- If you have unique packaging needs, ensure the supplier can tailor the machine accordingly.

- What About Onsite Visits or Demos?

- Witnessing a machine in action can give you deeper insights into its true capabilities.

Putting in the due diligence upfront helps you build a long-term partnership that boosts your ROI and packaging efficiency.

What Are the Future Trends and Innovations in Vertical Packaging Machines?

The packaging industry is continually evolving, and so will your operation. Here’s what to watch:

- Increased Automation & AI: Expect more self-optimizing machines with predictive maintenance and automatic performance adjustments.

- Greater Sustainability: Eco-friendly films, compostable materials, and energy-efficient systems will be in high demand.

- Enhanced Flexibility: Future machines will handle a wider range of bag styles and switch between products faster.

- Remote Monitoring & IoT Integration: Real-time data analytics will help you identify issues and optimize performance, often without leaving your office.

Staying on top of these developments ensures you’ll remain competitive and continue to deliver products that meet both market demands and environmental standards.Check know more about AI Packing Machine Here