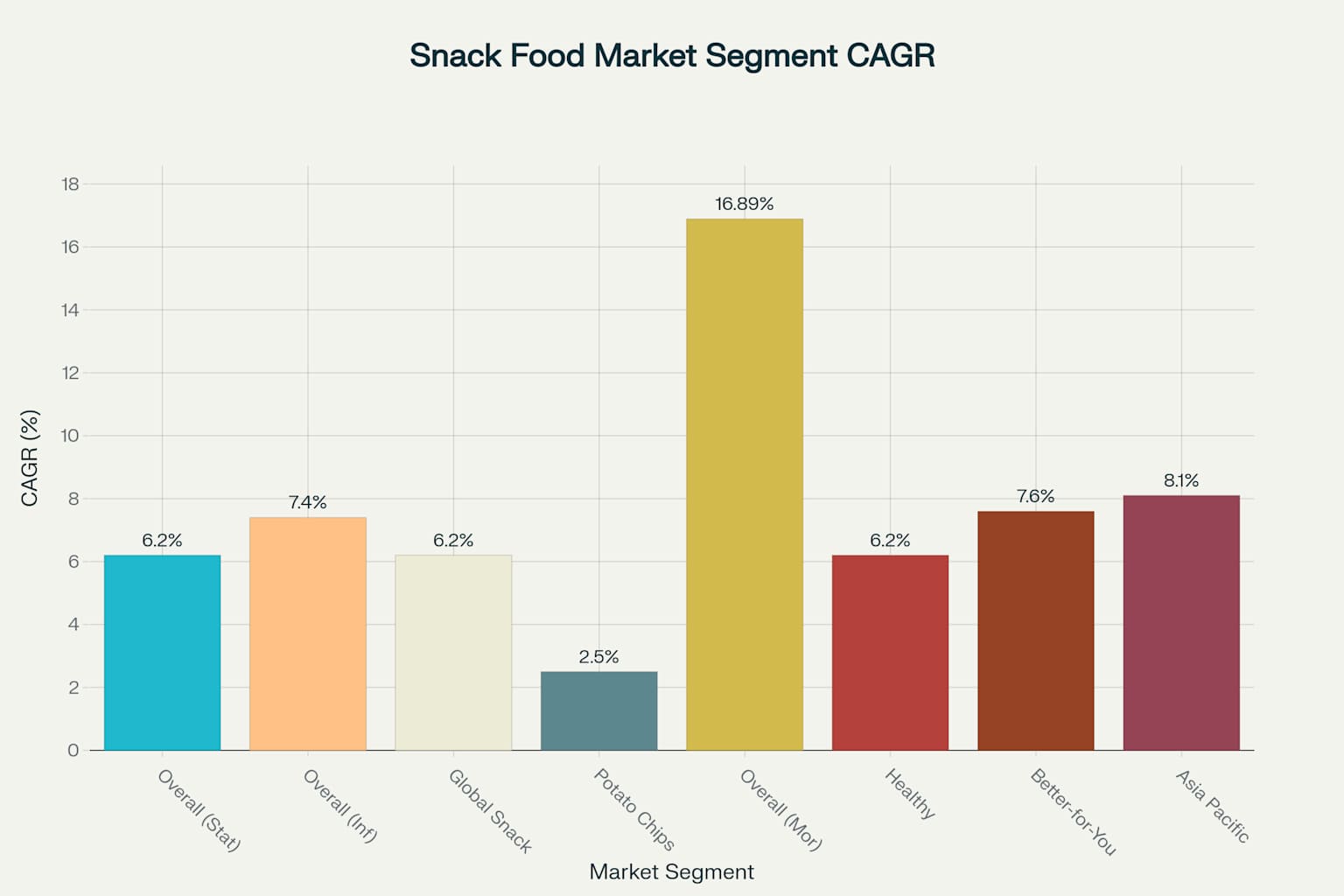

The global snack food market is experiencing robust growth projections across multiple research forecasts, with estimates ranging from conservative figures of 6.2% CAGR to ambitious forecasts exceeding 16% annual growth rate through 2030. This expansion is fundamentally reshaping how consumers snack, with 91% of global consumers incorporating snacking into their daily routines and 28% consuming multiple snacks per day. The industry’s evolution encompasses not only product innovation but also revolutionary advances in packaging technologies that enhance consumer experience while addressing sustainability concerns .

Global Snack Food Market Growth Projections by Segment (CAGR %)

Global Snack Food Market Projections and Growth Analysis

Market Size and Value Projections

The global snack food market demonstrates remarkable growth potential with Statista Market Forecast valuing the current market at $269.45 billion in 2025 and projecting steady growth at a CAGR of 6.20% through 2030. Infiniti Research provides complementary data, forecasting a substantial increase of $387.9 billion between 2024-2029, representing a 7.4% CAGR. The most aggressive projection comes from Mordor Intelligence, which estimates current value at $256.26 billion (2023) with anticipated growth to $559.26 billion by 2028, representing an unprecedented 16.89% CAGR.

The potato chips segment specifically, according to IMARC Group, is expected to grow at a more modest but steady 2.5% CAGR, expanding from $35.2 billion in 2024 to $44.0 billion by 2033. This focused segment analysis provides an important baseline for understanding growth dynamics within specific snack categories .

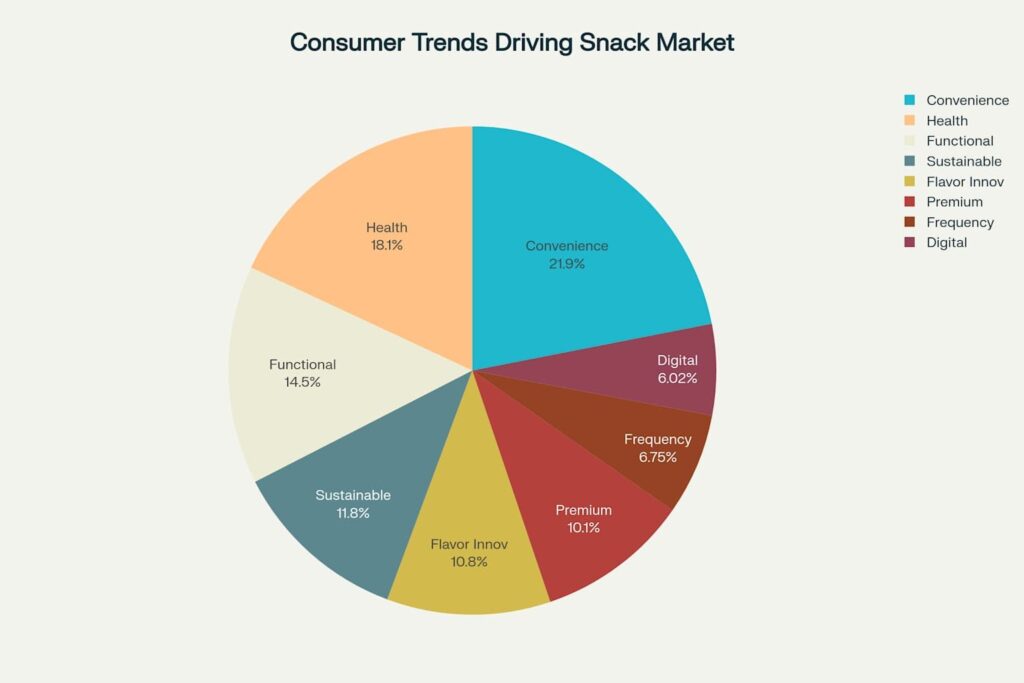

Key Market Drivers and Consumer Trends

The snack food market is experiencing a fundamental shift toward health-conscious consumption, with 75% of consumers actively seeking healthier snacking options . This trend encompasses functional snacks infused with protein, fiber, adaptogens, and probiotics, which have gained significant popularity among health-conscious buyers seeking nutritional value alongside convenience.

Convenience remains the dominant driver of snack consumption, with 91% of consumers embracing on-the-go snacking as part of their daily routine . This trend reflects the increasing pace of modern life, where traditional meal patterns are giving way to flexible snacking throughout the day. Environmental awareness significantly influences purchasing decisions, with 49% of consumers believing their buying behavior can positively impact the environment .

Regional Market Analysis and Growth Potential

The global snack food market exhibits distinct regional characteristics and growth patterns. North America commands the largest market share at 36%, driven by established consumption patterns and strong retail infrastructure. Asia Pacific represents 25% of the current market but demonstrates the highest growth potential with projected CAGR of 8.1% from 2025-2030.

The Asia Pacific snack food market is experiencing significant expansion due to several factors, including rapid urbanization, rising disposable incomes, and the increasing influence of Western snacking habits. Countries like China, India, Japan, and South Korea are experiencing particularly rapid growth in snack consumption, with manufacturers leveraging localized flavors such as masala and seaweed to capture market share.

Innovation and Product Development Trends

The industry is witnessing unprecedented flavor innovation, with 45% of consumers seeking bold, globally-inspired taste experiences. Popular emerging flavors include peri-peri, harissa, wasabi, and various ethnic seasonings that reflect increasingly adventurous consumer palates . This trend toward global flavor exploration is supported by growing international travel and cultural exchange .

Functional snacking has gained significant traction, with 60% of consumers seeking snacks with added health benefits . This includes protein-rich options, probiotic-infused products, and snacks containing superfoods like millet, quinoa, and ancient grains. The premium snacking segment, currently at 42% consumer adoption, represents significant opportunity for brands focusing on artisanal and gourmet options.

Comprehensive Analysis of Potato Chips Packaging Solutions

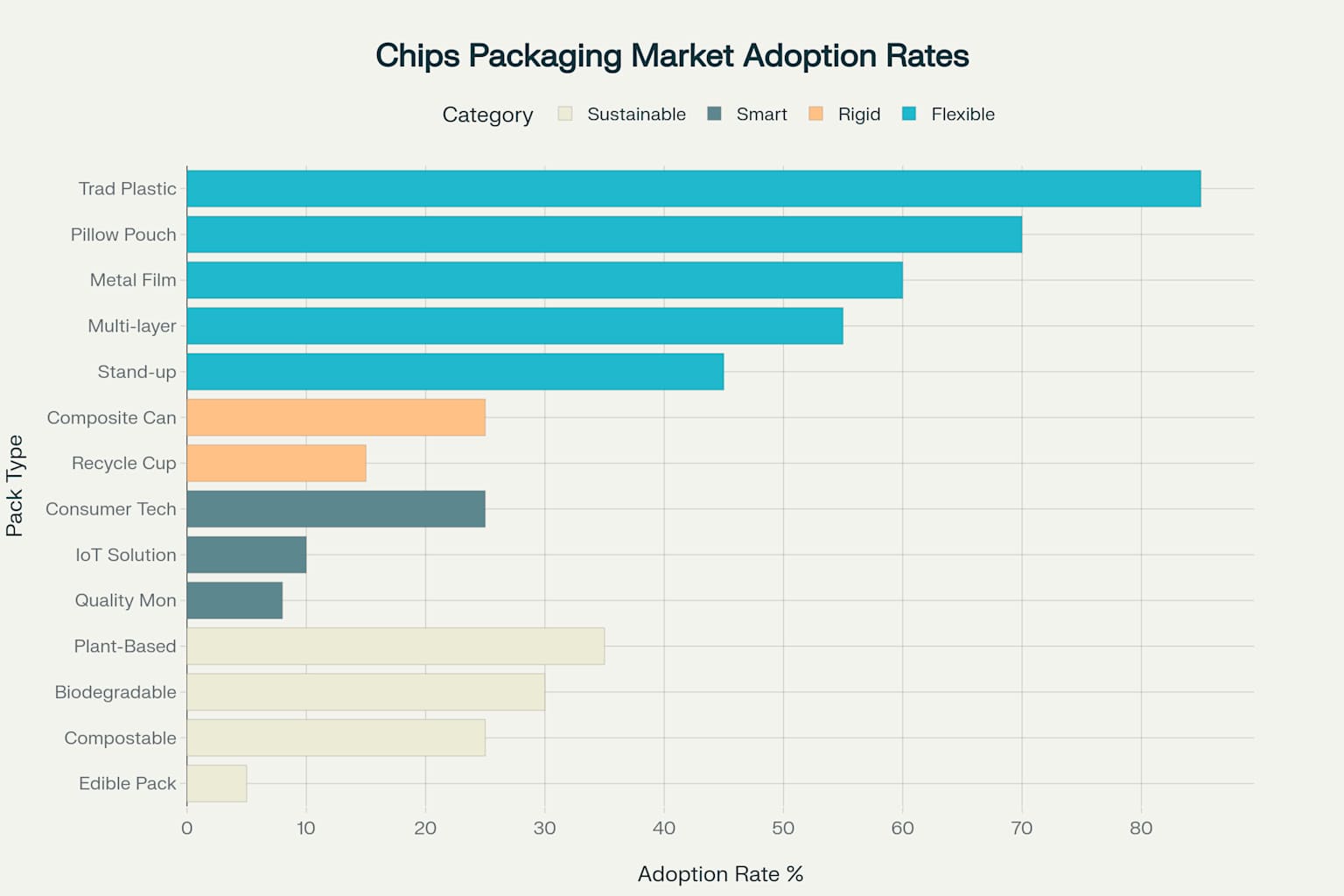

The potato chips packaging landscape encompasses diverse technologies and materials designed to preserve product quality, enhance consumer experience, and address environmental concerns . The industry utilizes four primary packaging categories: flexible, rigid, sustainable, and smart packaging solutions, each offering distinct advantages for different market segments .

Market Adoption Rates for Different Chips Packaging Solutions

Flexible Packaging Solutions

Flexible packaging dominates the chips market due to its versatility, cost-effectiveness, and excellent barrier properties . This category includes five primary types of solutions that collectively serve the majority of chips packaging needs .

Traditional Plastic Bags

Plastic bags using Biaxially Oriented Polypropylene (BOPP), Polyethylene (PE), and Polypropylene (PP) materials represent 85% market adoption in chips packaging . These materials offer lightweight construction, cost-effective manufacturing, and customizable shapes and sizes for various product requirements. The excellent sealing properties and printable surfaces make them ideal for mass production and brand marketing.

Metallized Film Pouches

Metallized film pouches, combining aluminum foil with plastic layers, achieve 60% market adoption due to superior barrier properties against moisture, oxygen, and light. These pouches extend shelf life significantly while maintaining excellent printability for premium brand presentation . The aluminum coating creates enhanced barrier performance but requires specialized recycling processes.

Specialized Pouch Configurations

Stand-up pouches using BOPP/VMCPP materials achieve 45% market adoption, offering self-standing capability and resealable options for enhanced consumer convenience . Pillow pouches, with 70% market adoption, provide simple design efficiency for Vertical Form Fill Seal (VFFS) machine operations. Multi-layer laminated films, at 55% adoption, offer customizable barrier properties for specific product protection requirements.

Rigid Packaging Innovations

Rigid packaging provides superior protection for delicate chips products, offering crush resistance and premium presentation capabilities . This category encompasses three primary solutions that address specific market needs for protection and convenience.

Composite Can Technology

Composite cans, featuring paper bodies with metal or plastic ends, achieve 25% market adoption by providing crush-resistant protection and stackable convenience . These containers offer resealable functionality and premium shelf presentation, making them ideal for stackable chips like Pringles . The multi-layer construction provides excellent structural integrity while supporting creative branding opportunities.

Recyclable Cup Solutions

Recyclable cups using PP construction with removable cardboard sleeves represent an innovative approach to sustainable rigid packaging, achieving 15% market adoption . These solutions offer reusable container functionality, quiet opening compared to traditional crinkly bags, and enhanced environmental appeal. The separable design enables efficient recycling with plastic cups and cardboard components processed through appropriate waste streams.

Sustainable Packaging Revolution

Sustainable packaging solutions are rapidly gaining adoption as environmental consciousness drives consumer and regulatory demands . These innovative approaches focus on biodegradability, compostability, and reduced environmental impact.

Biodegradable Materials

Biodegradable bags using PLA (Polylactic Acid), PHA (Polyhydroxyalkanoate), and starch-based materials achieve 30% market adoption . These materials naturally decompose under specific conditions, reducing environmental impact while maintaining functional performance. Plant-based materials derived from cornstarch and mushroom mycelium reach 35% adoption, offering renewable resource utilization and biodegradable properties.

Compostable Film Innovation

Compostable films using cellulose and seaweed derivatives achieve 25% market adoption, providing industrial or home compostable properties . Leading examples include Two Farmers’ eucalyptus cellulose films that decompose in 30-36 weeks in home composting systems or 11 weeks in industrial composters . These innovations address the challenge of traditional multi-layer films that resist recycling .

Edible Packaging Technologies

Edible packaging represents the ultimate zero-waste solution, currently achieving 5% market adoption as an emerging technology . Materials including seaweed, rice paper, and algae-based films offer consumable packaging that leaves no waste. This innovative approach provides unique consumer experiences while eliminating disposal concerns entirely.

Smart Packaging Technologies

Smart packaging incorporates advanced technologies to enhance consumer experience and product quality monitoring . IoT-enabled packaging solutions provide real-time monitoring capabilities and consumer engagement opportunities that transform traditional packaging into interactive platforms .

IoT-Enabled Solutions

IoT-enabled packaging integrating sensors and chips achieves 10% market adoption with rapidly growing potential. These solutions provide real-time monitoring of temperature, humidity, pressure, and other environmental conditions that affect product quality. Advanced features include tamper evidence, authentication verification, and supply chain transparency through blockchain integration.

Consumer Engagement Technologies

QR code and NFC integrated packaging achieves 25% market adoption by enabling smartphone-based consumer interaction . These technologies provide access to product information, promotional content, and brand engagement opportunities that enhance customer loyalty . Temperature-sensitive packaging with visual quality indicators achieves 8% adoption, offering immediate freshness verification for consumers

What Are the Different Types of Potato Chips Packaging Solutions?

Chips packaging is not one-size-fits-all. Several types of packaging solutions cater to different needs, such as preserving freshness, maintaining shelf-life, and offering consumer convenience. The most common types include flexible packaging, stand-up pouches, and vacuum-sealed bags. Each has its own advantages depending on the type of chips being packaged and the desired outcome for the product.

Flexible Packaging

Flexible packaging is the most widely used in the chips industry due to its ability to preserve freshness and provide cost-effective solutions. These packages are often made from materials like polypropylene, polyethylene, and PET, offering both durability and lightweight properties. The flexibility of this packaging also allows for easy customization in terms of size, shape, and printing.

Stand-up Pouches

Stand-up pouches are gaining popularity due to their resealable features and convenience. Consumers can easily store and reuse the packaging, which helps maintain the freshness of chips after opening. These pouches are often made from multi-layer materials that provide excellent barrier properties, preventing air and moisture from reaching the chips.

Why Is Sustainability Important in Chips Packaging?

Sustainability has become a central focus in the food packaging industry. As consumer preferences shift towards eco-friendly products, packaging companies are working to reduce environmental impact by using recyclable and biodegradable materials.

The Growing Demand for Eco-friendly Packaging

With more consumers prioritizing sustainability, companies that fail to adopt eco-friendly practices risk losing market share. The chips industry, known for its heavy reliance on plastic packaging, is under increasing pressure to innovate and switch to recyclable or biodegradable materials that reduce the overall carbon footprint.

Environmental Benefits of Recyclable Materials

Recyclable chips packaging helps reduce waste, conserve resources, and minimize pollution. By choosing materials like paper, cardboard, or biodegradable plastics, companies can significantly cut down on their environmental impact and contribute to a circular economy.

Top Chips Packaging Machine Companies to Consider

Choosing the right packaging machine is crucial for efficient production and consistent product quality. Some of the top companies in the chips packaging machine industry offer innovative solutions tailored to different production scales.

Popular Brands

- Bosch Packaging Technology: Known for providing high-quality packaging solutions for snack foods, Bosch’s machines are known for their reliability and performance.

- GEA Group: Specializing in automated systems, GEA’s packaging machines are perfect for small to large-scale operations.

- TNA Solutions: A leader in turnkey solutions, TNA is famous for providing advanced chips packaging equipment that integrates seamlessly with existing production lines.

- LTC PACK: We built to provide superior performance, flexibility, and reliability. Whether you need high-speed automated solutions for large-scale operations or smaller, more flexible machines for boutique productions, we’ve got you covered.

Why Small Businesses Love Mini Chips Packing Machines

Small businesses appreciate mini machines because they allow them to maintain high packaging standards without the need for large investments. These machines can handle small to medium-sized production runs, making them perfect for growing snack companies.

How to Do Chips Packaging for Small Business?

For small businesses, investing in the right packaging machine can make or break your ability to compete in the snack market. Understanding the various packaging solutions available can help small business owners make informed decisions.

Considerations for Small Business Packaging

- Scale of Operations: Small businesses should consider packaging machines that can handle smaller production runs but are still scalable as the business grows.

- Cost-Effectiveness: Small business owners need packaging solutions that provide value for money while maintaining quality and consistency in packaging.

- Customization: Being able to customize the packaging design can help differentiate your product in a crowded market.

A mini chips packaging machine can be a great option for small businesses looking for an affordable yet efficient solution to package their chips.

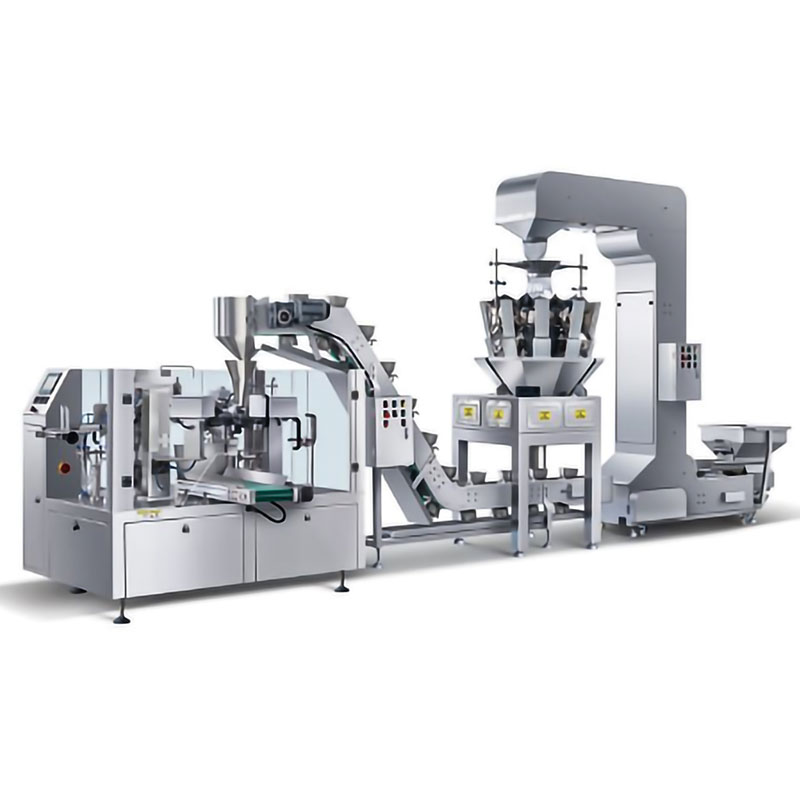

Premade Pouch Packing Machine vs Form Fill Seal Machine: Which Is Better?

When it comes to chips packaging, businesses often face a choice between a premade pouch packing machine and a form fill seal (FFS) machine. Both options come with their own set of advantages, depending on the production needs.

Premade Pouch Packing Machine

Premade pouch machines are ideal for companies that need high-quality, custom-shaped pouches. These machines are used to fill and seal pre-made pouches with chips, offering greater flexibility in terms of design and packaging options.

Form Fill Seal Machine

On the other hand, form fill seal machines are better for high-volume production. These machines create the bag, fill it with chips, and then seal it in one continuous process. FFS machines are faster and more efficient for large-scale operations.

The choice between the two depends largely on the production scale and packaging needs of the business.

How Much Does a Small Chips Packaging Machine Cost?

The cost of a small chips packaging machine varies based on its features, capabilities, and brand. Generally, the price range can be anywhere from a few thousand dollars to tens of thousands of dollars.

Factors Influencing the Cost

- Machine Type: Mini machines are usually more affordable than larger, more automated machines.

- Features: Machines with advanced features such as automatic weighing, sealing, and labeling tend to be more expensive.

- Production Speed: Higher-speed machines, capable of packaging more units per minute, often come at a higher price.

For small businesses, it’s important to balance cost with the features needed to ensure efficient packaging without overspending.

The Benefits of Recyclable Packaging in Chips Production

Recyclable packaging is gaining traction in the chips industry as both consumers and companies seek sustainable alternatives to traditional plastic packaging.

Environmental Impact of Recyclable Packaging

Recyclable packaging helps reduce the amount of plastic waste that ends up in landfills and oceans. This can significantly lower the environmental footprint of a chips brand and align with consumer preferences for sustainable products.

Consumer Preferences for Sustainability

As awareness about environmental issues increases, consumers are increasingly opting for products with recyclable or eco-friendly packaging. Offering recyclable chips packaging can help brands cater to this growing demand and build a more loyal customer base.

How to Select the Best Chips Packaging Material?

Choosing the right packaging material is key to ensuring the freshness, quality, and longevity of chips. Packaging materials such as flexible films, foil, and biodegradable plastics each offer unique benefits.

Considerations for Selecting Packaging Material

- Barrier Properties: The material should protect the chips from air, moisture, and light to ensure freshness.

- Sustainability: Consider the environmental impact of the packaging material. Recyclable or biodegradable options are increasingly preferred.

- Cost: While high-quality materials are essential, the cost must be in line with the overall budget and business goals.

Future Trends in Chips Packaging: What to Expect

The future of chips packaging will likely see increased adoption of sustainable materials, automation in packaging processes, and greater customization options for consumer brands.

Automation and AI Integration

With the rise of smart packaging machines, the future of chips packaging is moving towards automation and AI-powered systems that optimize the packaging process. These systems can reduce labor costs, increase production speed, and improve the accuracy of packaging.

Sustainable Packaging Innovations

In the coming years, companies will continue to innovate with eco-friendly materials and recyclable packaging designs. This trend will help align the industry with global sustainability goals.